Powder handling solutions for the food industry impact product quality, integrity, safety, and efficiency. Proper handling leads to uniform mixing, prevents contamination, and maintains hygiene standards. Further, it minimises waste and optimises production processes. Moreover, careful handling aids in maintaining the flavour, texture, and nutritional value of food products. As…

Material handling is a pivotal part of the supply chain process. They are needed to optimise the movement of goods and materials in manufacturing and storage facilities. A well-structured material handling system can improve customer service, reduce costs, and eliminate the risk of accidents. Diverter valves play a crucial role…

Material handling is a crucial process in warehouse settings. Industries like large retail facilities, storage facilities, manufacturing centres, and transportation yards, rely on material handling equipment. The equipment has undergone major improvement over any traditional mechanical technology. The aim of using it is to offer completely dust-free material transportation. Moreover,…

Pneumatic is defined as the usage of pressurised gas for mechanical motion. Pneumatic automation is used in industrial sectors

Pneumatic conveying systems and bucket conveyor systems are all used to deliver items in a vertical or inclined plane in an industrial plant.

Airborne diseases are becoming severe and fatal with the rise in air pollution. Therefore, the need to breathe cleaner air is becoming a necessity, especially in industrial facilities.

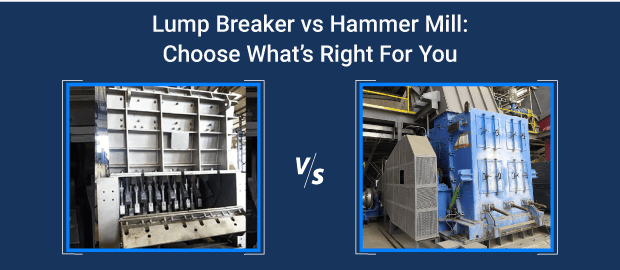

The modern manufacturing industries are using technology and mechanics to drive their production procedures faster while maintaining quality to get better income. Therefore, many automation are integrated into the production industries these days, and one of those revolutionary machinery is the industrial lump breaker. Its versatile use is critical in…

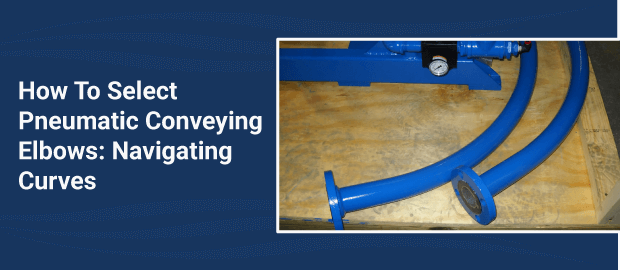

If you are new to the world of pneumatic conveying, you must know that it is a system that comprises various pipelines, ideal for moving products with the use of compressed air. Among all other components used in streamlining the function of a pneumatic system, an elbow is among the…

Diverter valves, as the name suggests, are used to divert the multiple pickup points when used in a pneumatic conveying system. With the use of this hardware, the materials are directed continuously, hygienically, and smoothly. The pneumatic conveying diverter valves have varying operations depending on the design of the hardware.…

Particle size reduction plays a very important role in transforming random-sized or bulky substances into uniform and small particles suitable for diverse applications. When done feasibly, the particle size reduction favourably alters the specific physicochemical properties of diverse raw materials. It is quite important for you to implement a well-designed…