Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

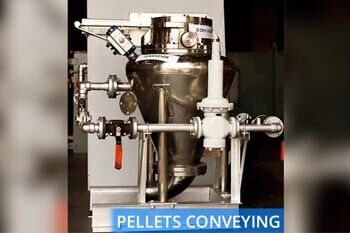

Dense Phase Pneumatic Conveying Systems

In dense phase conveying, powders, pellets, granules, flakes and other dry bulk materials are transferred through an enclosed pipeline. This system makes use of compressed air to transfer materials at high-pressure & low-velocity from a pressure vessel through a pipeline to single or multiple destinations (feeding points), wherein the product and the air is separated through a filter. In most cases, abrasive, friable or blended materials require a dense phase system, and the delivery process, for the products being conveyed, is quite gentle.

Macawber Engineering is an pneumatic conveying system manufacturer, we make use of the latest technology to design & manufacture high-quality dense phase conveying systems. Be it a complete system for bulk material handling or single component equipment, we can help you with both. Plus, when it comes to dense phase pneumatic conveying systems, we offer full-fledged services, including field service, start-up service, full-scale material testing, and spare parts.

Dense Phase Pneumatic Conveying - Key Features

- Dense phase conveyor is a user-friendly conveying system that requires low maintenance and has a low installation cost.

- It is ideally suitable for systems which convey materials over a long distance at high capacity to multiple feeding points.

- Since it works at low-velocity, dense phase pneumatic conveyor helps extend the service life of the systems, especially if it is conveying abrasive materials.

- Low conveying velocities in the pipeline also ensures that there is less wear & tear, thereby significantly reducing breakdown.

- It’s closed loop design helps eliminate dust, so there is no need for any robust dust collection systems.

- Compared to mechanical transfer, dense phase conveying system allows for handling more complex routes while ensuring dust free transfer.

Dense Phase Pneumatic Conveying Systems in India

Macawber Engineering is a leading manufacturer of dense-phase pneumatic conveying systems in India. It has in-depth knowledge and vast experience in designing reliable dense phase pneumatic systems and other systems such as dome valve manufacturers, fly ash handling systems, etc. We ensure to deliver the highest quality product – dense phase or lean/dilute phase conveying system – that meets stringent industry demands. If you require a robust dense-phase pneumatic conveying system, Contact with us today!