In the recycling of PET (Polyethylene Terephthalate) flakes, efficiency, cleanliness, and automation are critical for consistent production and quality. One such successful application was the design and installation of a PET flakes conveying system, engineered to transport PET flakes from Jumbo Bags to inline dryers in a PET recycling facility.…

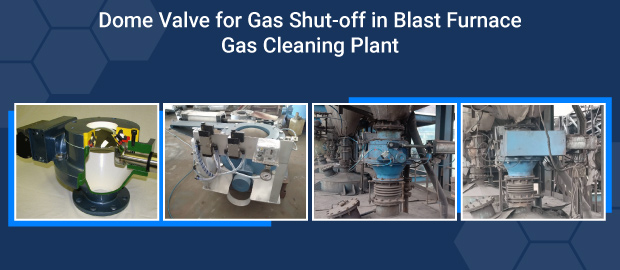

In the high-pressure, high-dust environment of a blast furnace gas cleaning plant (GCP), ensuring safe and reliable isolation of gas lines is critical. One of the most robust and efficient solutions for this demanding application is the dome valve, a specialised valve engineered for tough conditions where conventional valves often…

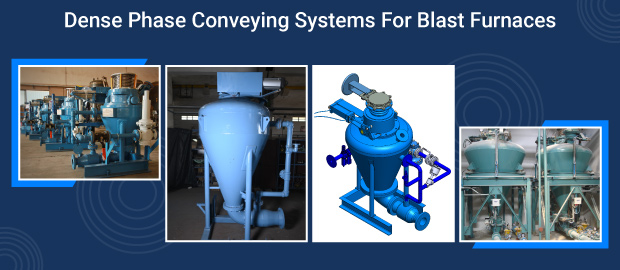

In the steelmaking industry, blast furnaces are at the heart of iron production. These massive, continuous reactors rely on the precise and consistent delivery of raw materials to function efficiently. These materials include fine powders, such as pulverised coal, hydrated lime, dolomite, various industrial dusts, and occasionally, fluxes or additives.…

Industrial batching systems are crucial in various industries, especially in manufacturing in the paint industry, chemical production, and pharmaceuticals. These precision batching systems are responsible for accurately weighing and mixing raw materials in precise quantities to produce a consistent product. In this blog, we will dive into some core concepts…

Ash handling is an essential part of industries that involve combustion processes, such as power generation, cement production, and steel manufacturing. These industries generate large amounts of ash that need to be efficiently handled to ensure smooth operations, minimise environmental impact, and comply with regulatory standards. The process, however, is…

Heavy powders are commonly handled in industries such as steel, power, foundry, refractories and construction chemicals. These include materials like dolomite, sand, quartz, feldspar, heavy soda ash, barite, iron dust and various such heavy dusts. Due to their dense, granular nature, these powders require specialised pneumatic conveying systems to ensure…

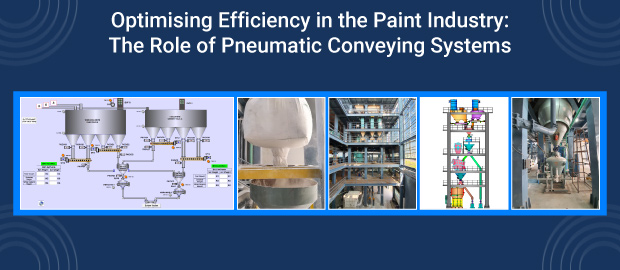

The paint industry faces numerous challenges when it comes to transporting raw materials, such as pigments, powders, and other additives, from one point to another. Traditional methods can be inefficient, costly, and prone to contamination. Pneumatic conveying for the paint industry offers a solution to these challenges, enabling smoother, cleaner,…

Pneumatic conveying systems play a crucial role in enhancing efficiency and safety in the steel manufacturing industry. Pneumatic conveying systems used to transport bulk materials like iron ore fines, lime, additives, bentonite, coal, coke dust etc. reduce manual handling, minimise dust, and streamline operations. This blog aims to discover how…

In the proper functioning of a pneumatic conveying system, its various components, like pneumatic conveying vessels, diverter valves, vent filters, silo, and hoppers play a major role. For the whole system to work smoothly at an industrial level, high-quality fabrication of individual components is necessary. These systems are used for…

In the world of industrial processing, efficient material handling is crucial for operational success. Macawber Engineering has emerged as a leader in sand conveying systems, renowned for its innovative technology and unwavering commitment to quality. This blog delves into the key factors that set Macawber apart and its impact on…