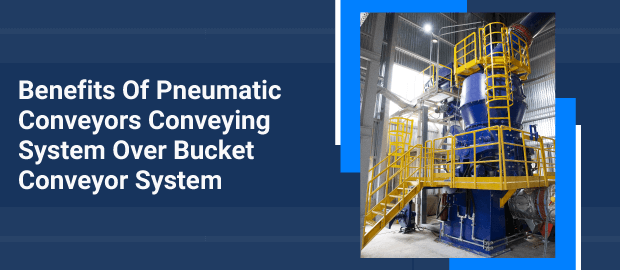

Pneumatic conveying systems and bucket conveyor systems are all used to deliver items in a vertical or inclined plane in an industrial plant. These systems are usually used in production units and the manufacturing industry. The bucket conveyor has buckets for carrying the material, while the pneumatic conveyor uses air pressure to automatically transfer material.

There are many features of the pneumatic conveying system which are advantageous in comparison to the bucket conveyor. In this article, you will learn why pneumatic conveyors are better than bucket conveyor systems in industrial settings.

A] What Are Bucket Conveyor Systems?

Bucket elevators or bucket conveyor systems are industrial conveyor belts that carry items on an inclined or vertical plane. These elevators have a simple setup of bucket containers on conveyor belts, and the system is used to lift raw material from a lower plane to a higher plane. The buckets on the conveyor belt are the main holding component, and their sizes differ on the basis of the item number and size they carry.

The belt on which these carrying buckets are put drives the buckets on an inclined plane. The power for the simple bucket elevator comes either from pulleys or power-generating electric motors. While pulleys were used earlier to make bucket elevators work, these days, the most used version is the electric-powered bucket conveyor.

The bucket conveyor has many applications in industrial plants. For example, bucket elevators are used to carry agricultural raw materials and feed like grains. These grain elevators are used to transport bulk agricultural products or materials from one place to a massive storage space. Bucket elevators are also used in mining and quarrying, so they can carry ore and minerals from one site to another high-level site.

Switch to pneumatic conveyors to minimise breakdowns and improve productivity.

B] Problems With Bucket Conveyors

A bucket elevator conveyor belt works amazingly under certain conditions, but the same system also comes with some disadvantages. For example, it has some constraints and cannot be used for fragile material transportation. The bucket elevators might be rigid in working and could run into problems when constantly used.

The bucket elevator has limited space and carrying capacity as it is not suitable for carrying high-density bulk material on it. The bucket conveyor system is not the right system to use for fragile item transportation as shocks from the rigidity of the belt system can lead to damage to fragile items.

Another disadvantage that operators will tell you about is the breakdown of bucket elevators. The bucket conveyor belt system often runs into operational problems and might need a complete maintenance session to run smoothly again. Without regular maintenance, the bucket elevator system becomes too prone to breakdowns and does not work properly, leading to supply chain problems.

The components used in this simple conveyor system are very common and could get damaged. If the components get damaged, the time needed to repair the system might cause delays in the production process and supply chain management. One needs to change the bucket conveyor system to avoid these drawbacks.

C] Advantages Of Pneumatic Conveyor Systems

Pneumatic conveying is a great alternative to bucket conveying because it uses Pneumatics or air pressure to transport items on an inclined plane. As it uses gentle air pressure, the handling of items, especially fragile ones, on this system is better than that of bucket conveyors.

A pneumatic conveyor is specifically used to convey fragile and high-density material from one place to the other because it is great for handling. The pneumatic conveyor belt is best for carrying finished items in the supply chain as it minimises damage.

The pneumatic conveyor is also known to be flexible in its use. The pneumatic conveyor belt is versatile and can be modified to carry items vertically, horizontally and on an inclined plane.

Another good advantage of the pneumatic conveyor is its closed-loop operations. Because of the closed-loop environment around which it operates, the pneumatic conveyor keeps the items away from dust. So, the items are transported very easily without any damage or dust collection on them. Apart from the protection they offer from dust, the material from which the pneumatic system is created is also a major advantage.

The pneumatic conveyor belt is usually made of stainless steel, which can be sanitised very easily. Because of the ease of transport and the extra care for cleanliness and hygiene, pneumatic conveying systems are often recommended over bucket conveyors. These advanced conveying systems are very sturdy and do not need maintenance very frequently. All of these advantages make the pneumatic conveying system a very useful system for production units.

D] What To Consider Before Investing In A Pneumatic Conveyor?

Before you buy a pneumatic conveyor conveying system, now that you know its benefits, you should consider the pneumatic conveyor manufacturer from which you are buying it. Buy the pneumatic conveying system from a reputed seller who takes care of its quality and maintenance. Choose a conveyor system that shows minimal downtime and works efficiently in different environments and inclines.

Research the many manufacturers of this system and find one that does not compromise on quality. Buy one when you find it within a reasonable price range and with all the necessary features. Do not rush the decision to buy the pneumatic conveyor till you have found one that fits your needs.

Switch to pneumatic conveyors to minimise breakdowns and improve productivity.

Conclusion

In this blog, a comparison is drawn between bucket conveyors and pneumatic conveyors. After a comparison, it is known that there are some distinct drawbacks to the bucket elevators, which do not make them the best option for industrial logistics. While the bucket conveyor is good for raw material supply in certain industries, it is not as versatile as the pneumatic conveying system.

The pneumatic conveyor has multiple advantages and features which are great for a range of industries and supply chain management. It is best to invest in a pneumatic conveying system, but before buying one, you should find a reputed seller with a reasonably priced product. To get the best pneumatic conveyor belts in the market, contact us and browse through our products.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.