Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

Vacuum Conveyor Systems

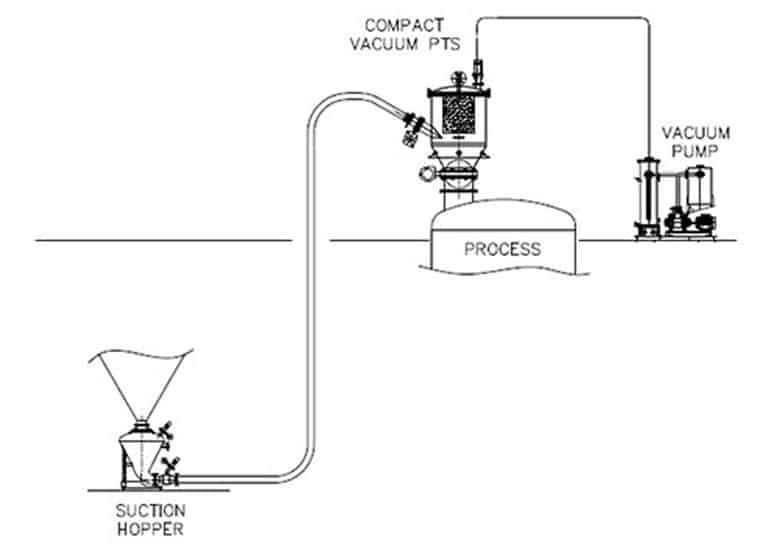

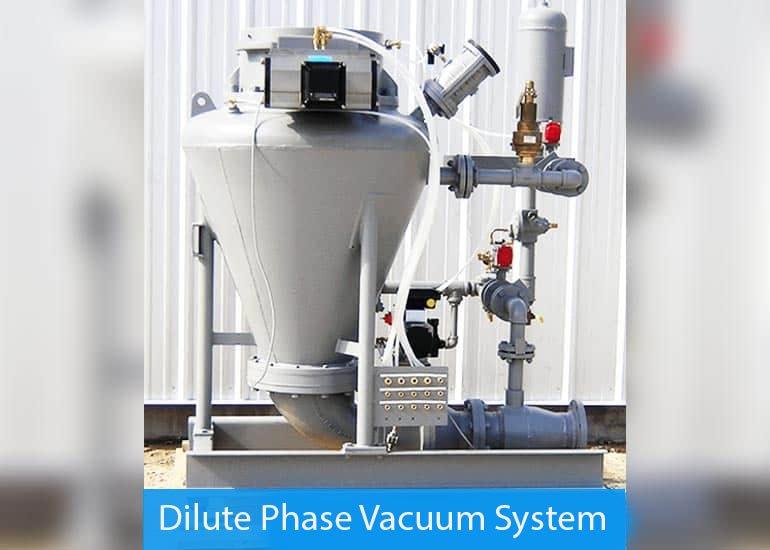

We are a leading manufacturer of vacuum conveyor systems in India offering a high-performance modular design that is well-suited for the transfer of all material applications including powder, pellets, dust, granules, flaky ingredients, pigments, among others. In vacuum transfer, materials are sucked through the pipeline at high velocities. Thus, we offer vacuum conveyors that utilize proven optimal designs to safely and hygienically transfer bulk materials.

We provide a complete line of vacuum conveyor systems ranging from small portable units to larger units as per the requirement. Our vacuum transfer systems are offered for a range of conveying distances and are designed to work for various materials. Our vacuum loading systems are also easy to install, operate and maintain. Plus, they are lightweight & compact and can easily fit into even the tightest space.

Vacuum Pneumatic Conveying Systems - Key Features

- Our vacuum conveyor systems are energy efficient, which ensures less operational cost.

- They are simple to install & control and easy to dismantle & clean.

- It comes with advanced filter technology, and the closed-system approach ensures dust-free material transfer.

- We have varying models & designs of transfer rates & distances based on application-specific data and can be custom built to your requirement.

- The vacuum loader system is completely reliable, offers continuous flow and is fairly gentle on the material.

- With its dust-tight seal, it prevents material contamination. Plus, it prevents accidental spillage and exposure, thus ensuring that the system operators are protected at all times, especially when handling hazardous materials.

Vacuum Conveying Systems in India

Frequently Asked Questions

A pneumatic vacuum conveyor is a system that uses vacuum pressure to transport bulk materials—such as powders, granules, or pellets—through a pipeline. It generates suction at the intake end to pull materials into the system and move them to a discharge point. This type of conveying system is particularly effective for handling fine or fragile materials, as it minimizes product degradation. It is often used in industries like food processing, pharmaceuticals, and chemicals where cleanliness, dust control, and gentle handling are important.

The Pneumatic vacuum conveyors offer an array of benefits, including safety, cleanliness, gentle conveyance, low maintenance, flexibility, dust-free operation and minimal space requirement.

Related Products

Industriel is a pioneer in design-build specializing in architecture and construction services. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

Industriel has a brilliant record in responding to complex customer requirements. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

We work to reduce air emissions associated with our operations and the products we deliver. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.