Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

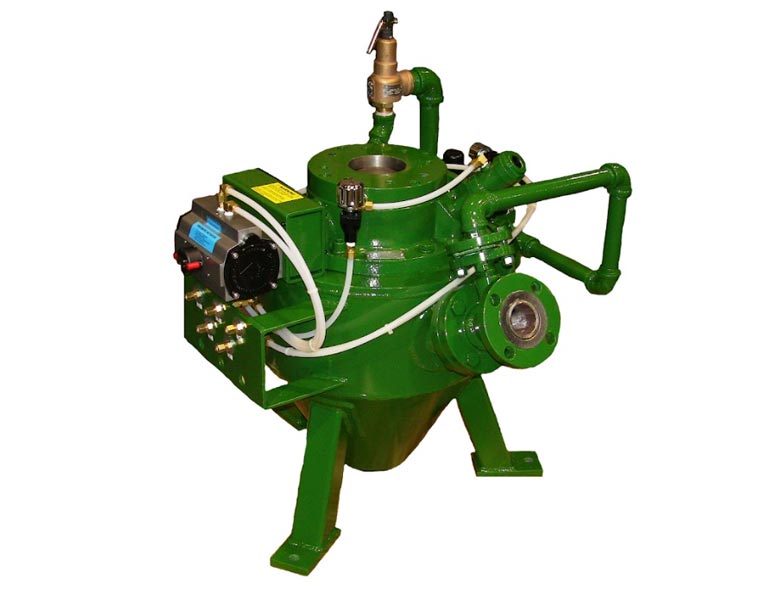

Pneumatic Conveying Sandpump

Why Choose Macawber Pneumatic Conveying Sandpump?

Our Sandpump for pneumatic conveying can be fully-customised as per the required needs. It comes fully assembled, which helps lower the cost of installation and saves time. This system is energy efficient and requires minimum maintenance. Also, since it can be positioned directly below shakeout tables and reclaimers, it offers seamless integration into existing process layouts. More importantly, our Sandpump is fitted with a robust Dome Valve that helps reduce wear & tear, air consumption, and reduces maintenance downtime.

Sandpump for Pneumatic Conveying: Key Features

- It is fully assembled and rigorously tested before shipment.

- A compact machine with a top discharge, sand conveying system is well-suited for retrofit applications with minimal headroom.

- It is easy to set up, comes with automated or on-demand operation, and requires minimum maintenance.

- It is the most cost-effective way to move (transfer) sand with low air consumption.

- It can handle sand temperature rating up to < 660°F (350°C).

- The standard pressure rating of this system is up to 100psig (7barg).

- The enclosed design of the pneumatic conveying system ensures that the sand is well-contained, thereby minimising spillage and dust leakage.

- Apart from offering safe & secure transfer, it also ensures minimal wear and tear of pipe and others components.

- Ratio of conveying vessel to pipe dia. to suit distance, the material characteristics, capacity & grade of sand.

- Since it can achieve very high phase densities (material-to-air ratio), Sandpump is commonly used in foundries.

- This dense phase pneumatic conveying system is suitable for resin coated sand systems.

Product Video Watch Now

Industriel is a pioneer in design-build specializing in architecture and construction services. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

Industriel has a brilliant record in responding to complex customer requirements. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

We work to reduce air emissions associated with our operations and the products we deliver. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.