Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

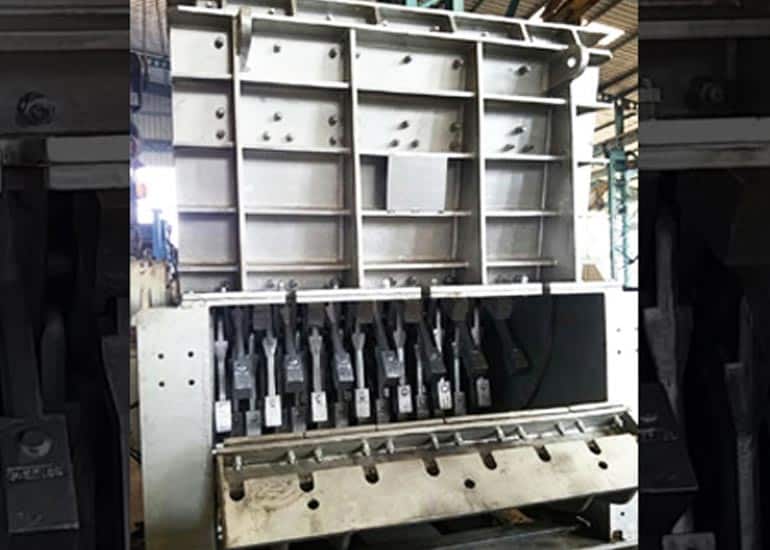

Lump Breakers & Industrial Hammer Mill Crushers Manufacturer

Lump Breakers are also known as Lump Crushers. They are used for breaking or reducing lumps of materials like clinker ash, lime chunks, chunks of bonded chemical salts, chicory, and other similar weak breakable materials. They enhance downstream processing by breaking the materials into smaller and uniform particles.

Lump Breakers - Key Features

- They have a robust design and construction that makes them apt to be used as a light-duty crusher or a heavy-duty lump breaker.

- Lump breakers can be installed as stand-alone components when required as they are located immediately above the vessel or can be incorporated inside the existing plant layout and system for discharge.

- It can process an array of materials, including sugar, chemicals, cement, ceramic powders, and more.

- The design of the lump breaker features fixed and rotating blades that can be easily replaced.

- They offer a simple, reliable, durable, and highly economical means to condition materials consisting of lumps due to production, storage, transport, etc.

- Lump breakers offer enhanced product quality at a relatively lower cost.

- Installation and maintenance are easy.

Lump Breaker - Application Areas

- Applications in Industry - size reduction for fertilizers, salt, sugar, detergents, etc.

- Mining Industry - crushing of common materials such as minerals and chemicals.

- Construction Industry - used to break materials that tend to form lumps, such as cement, and ensure a smooth supply of bulk materials.

Hammer Mills Manufacturer In India

Hammer Mills are the oldest, most widely used size reduction machine with a series of hammers. These hammers are fixed on a central shaft and are enclosed securely inside a hard metal case. They are used to break and crush feed materials and offer uniform size reduction. These heavy-duty machines are mostly used for material processing in construction, chemical, cosmetic, mineral and mining industries. At Macawber, we manufacture and supply hammer mills, jaw and cone crushers, impactors, screens, and feeders.

Hammer Mills - Key Features

- The feeding mechanism, control box, crushing hammers, and pulverizer screens are the main components of hammer mills.

- They are designed to be durable and reliable.

- They cannot be used to grind sticky materials.

- They operate at a low temperature to protect the nutritional value of the feed ingredients.

- The requirements concerning energy are low, making them cost-effective.

- The machine is easy to install and operate.

- Large hammer mills are driven either by diesel or electric motors, ranging from 2000 to over 5000 horsepower (equivalent to 1.5-3.7MW).

- They offer high capacity and high reduction ratios.

- They occupy a small area, making the maintenance and cleaning of mills easier.

Hammer Mills - Application Areas

- Used for material size reduction to obtain uniform sizes.

- Produce intermediate powder grades.

- Ideal for solids like coal, limestone and similar materials.

- Is also used as a part of Flash drier mill circuits involving drying & size reduction.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.