Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

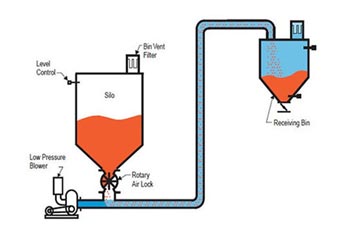

Dilute Phase Pneumatic Conveying System

Unlike dense phase conveying, lean/dilute phase conveying is well-suited for handling less abrasive, light & uneven materials such as coffee grounds, sawdust, flour, chips & flakes. In lean phase conveying, granular bulk materials or dry powder is transported through a pipeline to the destination at low pressure and high velocity. This conveying system also supports flexible pipe routings. Also, since the entire process is carried out in an enclosed environment, it makes dilute phase pneumatic conveyor a clean and safe mode for transportation.

At Macawber Engineering offer a wide selection of lean / dilute phase conveying systems such as pressure dilute phase, vacuum dilute phase, a combination of both pressure and vacuum as well as vacuum sequencing. Each has its own advantages and which to choose would depend on the process requirement.

Dilute Phase Pneumatic Conveying System - Key Features

- Dilute phase systems are best suited for lower capacities and over low to moderate distances.

- Dilute/Lean phase conveying are cost-effective systems that require a small capital investment and has a lower installation cost.

- They are simple to operate, comes with flexible routing, and the closed-loop eliminates dusting.

- Dilute phase pressure conveying is ideal for conveying materials from a single source to multiple locations.

- While dilute phase vacuum conveying is ideal for conveying materials from multiple sources to a single destination.

- These pneumatic conveying systems require minimal headroom (height) at the feed point.

Lean Phase Pneumatic Conveying Systems in India

As an industry leader, we offer superior quality dilute phase pneumatic conveying systems in India. Depending on the material that needs to be conveyed, we can help you pick the right conveying system that works best for your needs. Therefore, send in your requirement at sales@macawberindia.in or connect with us if you have a query or need any further information.

Frequently Asked Questions

Related Products

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.