Pneumatic Conveyor For Steel

- Home

- Industries

- Steel

Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

Industry Overview

The steel industry is a cornerstone of modern manufacturing and infrastructure development,playing a vital role in the global economy. Steel is renowned for its strength, durability, and versatility.

From construction and automotive manufacturing to machinery and packaging, it is essential in various applications. Bulk powder handling is crucial in steel manufacturing, particularly in processes requiring recycling, conveying, injecting, precise dosing, and mixing of powdered materials.

These powders, including iron ore fines, additives, and metallurgical coke dust, are vital for producing high-quality steel. Effective handling of these materials is essential for maintaining production efficiency, ensuring product consistency, and optimising operational workflows.

A] Solutions Offered by Macawber

- Pellet Plant

Macawber is a well-regarded manufacturer of pneumatic conveying for the steel Industry and has supplied various pneumatic conveying systems for pellet plant powders, including iron ore dust, pellet dust, bentonite, and lime, with capacities ranging from 1 to 120 TPH.

- Sinter Plant

As a leading supplier of pneumatic conveyors for the steel industry, we have successfully conveyed various sinter plant dust and powders, such as iron ore, lime, sinter dust, coke, and dolomite, to dedicated storage silos over distances of approximately 800 meters.

- Calcined Lime Conveyance

Calcined lime, or quicklime (CaO), is critical in steel manufacturing. Macawber successfully conveyed calcined lime from the lime calcination plant to steel plant subunits over a distance of about 1,000 meters. Macawber’s high-capacity, long-distance pneumatic conveying solutions excel in calcined lime conveyance.

- Blast Furnace

The blast furnace generates high-temperature and high-pressure gases that are directed to a gas-cleaning plant. In the gas cleaning plant, a gravity dust catcher or cyclone separator is installed for effective dry scrubbing of gases coming from the Blast furnace. Macawber’s inflatable seal-type pressure-rated dome valve is engineered to handle the blast furnace’s dust effectively.

- Basic Oxygen Furnace

Pneumatic conveying systems are for transferring flux materials, such as lime and dolomite, to the Basic Oxygen Furnace (BOF). Macawber’s conveyor systems are made to handle BOF dust using its core conveying capabilities and patented dome valves.

- DRI Fines Transfer

Macawber’s pneumatic conveying systems can transfer Direct Reduced Iron (DRI) fines & dust over a distance of about 150 meters to storage silos.

- Steel Melt Shop

For steel melt shop, Macawber, a renowned pneumatic conveying systems manufacturer, has designed highly effective dense-phase pneumatic conveying systems to transfer dust from bag filters and gas mixers to a common dust storage silo. Additionally, our system is equipped with a bulker unloading system to transfer coke breeze from bulkers to storage silos.

- Coke Oven Plant Efficiency

Macawber offers conveying systems for conveying coke dust generated in the coke oven plant to storage silos for reuse successfully.

Enhance efficiency and reliability in your steel plant with our advanced pneumatic conveying solutions.

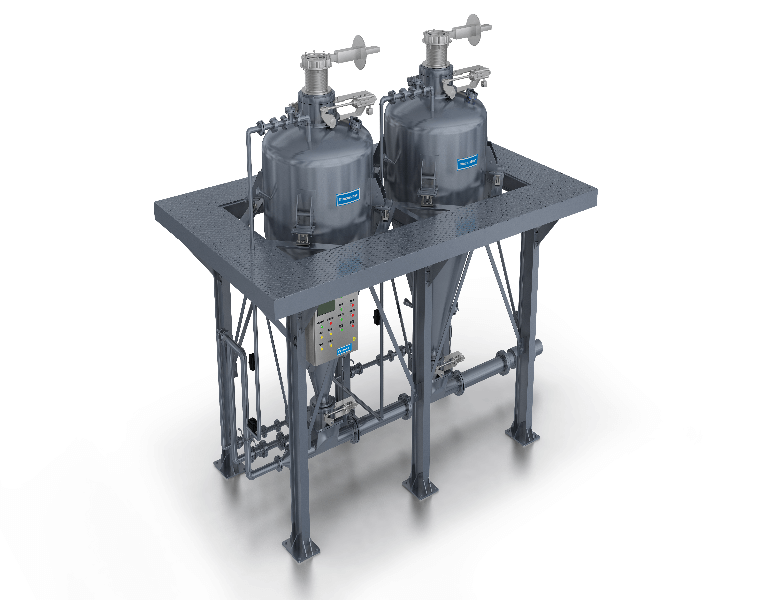

B] Macawber Products We have Supplied to an Array of Industries

- Bulker unloading systems

- Dome valve type Double dump valves

- Weigh feeders

- Wear-resistant bends

C] Unique Selling Points (USPs) of Our Design

1. ASME Compliance

Macawber emphasises ASME standards when designing pressure vessels for pneumatic dense-phase conveying, ensuring safety, efficiency, and compliance. Adhering to specific codes and guidelines guarantees the reliable operation of pneumatic conveying in the steel industry.

2. Precise & Dependable engineering

Macawber’s expertise lies in the precise engineering of vessel internals, vessel model design, pipe size selection, and vessel and pipeline fluidisation design. We are bound to offer dependable and robust engineering that lasts a lifetime.

3. Dome Valves with Hard Coating

The dome valve, crucial for regulating bulk powder flow, is the most wear-prone component. Macawber’s dome valves feature special hard coatings tailored to material properties and customer requirements, including ceramic, tungsten carbide, and frit coatings.

4. Heavy-Duty Design for Longevity

Macawber’s pneumatic conveying systems have been successfully supplied to the Indian steel industry for over 30 years, thanks to our heavy-duty design that extends equipment lifespan.

5. Lined Pipes and Bends

Due to the abrasive nature of bulk powders like lime, bentonite, dolomite additives, and various dusts, careful handling is essential in steel manufacturing. Macawber offers lined pipes and bends tailored to application specifics, reducing wear and tear on these components.

6. Optimal Sizing Design

Based on the required conveying capacity and corresponding air requirements, Macawber optimises vessel and pipeline sizes to meet critical performance parameters and energy efficiency.

7. Healthy Filtration Area

Proper venting of air is essential before material is dropped at reception points. An inadequate filtration area can lead to back pressure and system malfunctions. Macawber prioritises a healthy filtration area for adequate venting.

8. Accurate Weigh Feeders

Macawber’s weigh feeders ensure precise material dosing at the right times during the steelmaking process, optimising the steel product’s chemical composition.

Enhance efficiency and reliability in your steel plant with our advanced pneumatic conveying solutions.

FAQ's

The pneumatic conveyor system works by pushing or pulling iron ore fines, additives, and metallurgical coke dust. It uses compressed air to convey the various steel manufacturing essentials.

The Pneumatic conveyor offers the steel industry an array of benefits, such as safety, lower initial cost, flexibility, pollution reduction, and easy installation.

Yes, our Pneumatic conveyors are engineered to handle different types of steel materials, including heavy, friable, and abrasive materials.

Yes, periodic maintenance is required to prolong the life of Pneumatic conveyors and maintain their optimal work efficiency.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.