Pneumatic Conveyor For Glass

- Home

- Industries

- Glass

Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

Glass Conveying Systems

The glass industry in India is a vital part of the manufacturing sector, producing container glass, flat glass, and specialty glass for diverse applications. Driven by growth in construction, automotive, and packaging sectors, it combines traditional craftsmanship with modern technology, contributing significantly to exports and domestic industrial development.

Pneumatic conveying in the glass industry plays a critical role in modern glass industry material handling, enabling efficient, dust-free transport of bulk solids like silica sand, soda ash, and limestone. It ensures a consistent feed to batch houses, improves plant hygiene, reduces material loss, and minimises manual handling. Doing so enhances productivity, safety, and reliability in raw material handling across glass manufacturing processes.

Bulk Materials in the Glass Industry

The following materials are used in precise proportions to produce various types of glass for industrial and consumer applications.

- Silica Sand: Primary component, provides silica (SiO₂) for glass formation

- Soda Ash (Sodium Carbonate): Lowers the melting point of silica

- Limestone (Calcium Carbonate): Adds durability and chemical stability

- Feldspar: Improves hardness and resistance

- Dolomite: Provides magnesium and calcium, enhancing strength

- Borax: Lower melting temperature & enhances thermal & chemical durability

- Alumina: Increases chemical resistance

Improve glass manufacturing efficiency with our precise and dust-free pneumatic conveying solutions.

Solutions offered by Macawber

- 1. Dense-phase pneumatic conveying system

Dense phase conveying for glass manufacturing is ideal for abrasive bulk materials like silica sand, soda ash, and dolomite. It uses low-velocity, high-pressure air to move materials in slug flow, minimising wear on pipelines and preserving material integrity. This solution ensures reliable, long-distance transport with reduced maintenance and operational downtime. We offer dense phase solutions with capacities ranging from 1 TPH to 25 TPH over distances of up to 100 metres, subject to application. Learn more about our complete range of Dense Phase Pneumatic Conveying Systems.

- 2. Lean-phase pneumatic conveying system

Dilute phase systems transport lighter, less abrasive materials, such as feldspar and alumina, using high-velocity air, making them well-suited for applications typically handled by lean phase pneumatic conveying systems. In this system, material is suspended in the airflow, allowing continuous, low-pressure conveying. It’s suited for applications where material degradation is not a concern, offering flexible routing and easy integration.

- 3. Batch Feeding Systems

Batch feeding systems deliver precise quantities of raw materials into the batch house or furnace. Integrated with weighing and metering controls, they ensure accurate formulation of glass batches. These systems improve process consistency, reduce waste, and support automation in glass production, leading to higher quality and operational efficiency.

- 4. De-dusting system

Effective dust collection is critical when handling fine, powdery glass raw materials. Integrated filtration systems capture airborne particles during conveying, improving plant hygiene and worker safety. They help manufacturers comply with environmental regulations, reduce dust-related wear on equipment, and maintain the cleanliness of sensitive production areas.

- 5. Automation

Macawber’s automated pneumatic conveying systems enhance operational efficiency, accuracy, and safety, making them integral to advanced conveying systems in glass manufacturing. By integrating sensors, controls, and real-time monitoring, we optimise material flow, reduce human intervention, and ensure precise delivery, all while minimising downtime and improving overall reliability.

Macawber Products Supplied

- Denseveyor

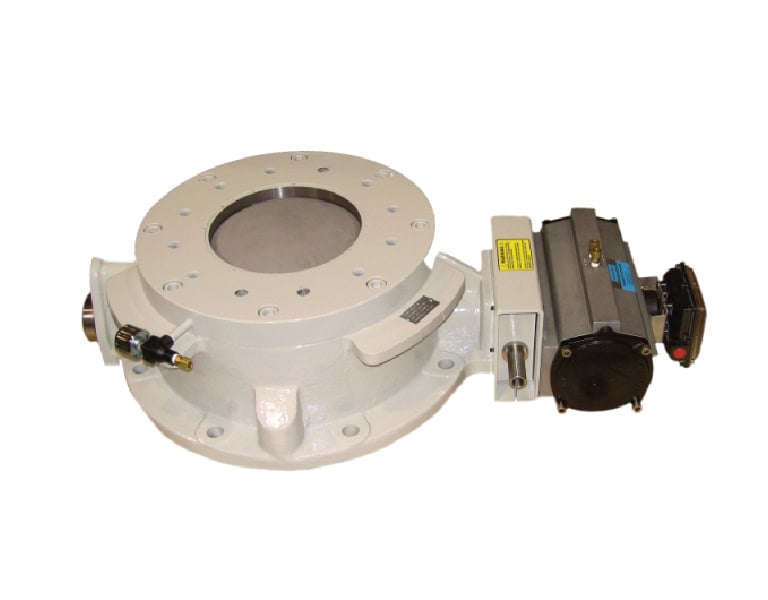

- Dome valves

- Diverter valves

- Bag filters

- DV-type Diverter valve

- Wear-resistant bends

- Bin vent filters

- Loss In Weight Feeders

- Gain In Weight Feeders

- Screw Conveyor

As one of the top glass industry pneumatic conveying system suppliers in India, we offer systems that are trusted by millions of national and international customers for their performance and durability.

Unique Selling Points (USPs) of Our Design

- ASME Compliance

Macawber emphasises ASME standards when designing pressure vessels for pneumatic dense-phase conveying, ensuring safety, efficiency, and compliance. Adhering to specific codes and guidelines guarantees reliable operation.

- Dome Valves

The dome valve, crucial for regulating bulk powder flow, is the most wear-prone component. Macawber’s dome valves feature special hard coatings tailored to material properties and customer requirements, including ceramic, tungsten carbide, and frit coatings.

- Heavy-Duty Design for Long Life

Macawber’s pneumatic conveying systems have been successfully supplied over the past 30 years across the Indian glass industry, thanks to a focus on heavy-duty design that results in extended equipment lifespan.

- Optimal Sizing Design

Based on required conveying capacity and corresponding air requirements, Macawber optimises vessel and pipeline sizes to meet critical performance parameters and energy efficiency.

- Healthy Filtration Area

Proper venting of air is essential before material is dropped at reception points. An inadequate filtration area can lead to back pressure and system malfunctions. Macawber prioritises a healthy filtration area for efficient venting.

Improve glass manufacturing efficiency with our precise and dust-free pneumatic conveying solutions.

Conclusion

Pneumatic conveying systems have revolutionised material handling in the glass industry, offering dust-free transport, precise batch formulations, and enhanced operational efficiency. Macawber’s comprehensive solutions, backed by 30 years of expertise and ASME-compliant designs, address the unique challenges of glass manufacturing. From abrasive silica sand to delicate powders, these systems ensure material integrity while maximising productivity. Contact Macawber today to discover how their proven pneumatic conveying systems can revolutionise your material handling processes and enhance operational efficiency.

Frequently Asked Questions

Pneumatic conveying uses pressurised air to transport bulk glass raw materials like silica sand, soda ash, and limestone through enclosed pipelines. It enables dust-free, automated material handling from storage to batch houses, ensuring consistent feed rates and improved plant hygiene.

Common materials include silica sand (primary component), soda ash, limestone, feldspar, dolomite, borax, and alumina. These vary in abrasiveness and flow characteristics, requiring different conveying approaches: dense phase for abrasive materials and lean phase for lighter components.

Glass plants use dense phase systems for abrasive materials like silica sand (low velocity, high pressure) and lean phase systems for lighter materials like feldspar (high velocity suspension). Batch feeding systems with weighing controls ensure precise formulations.

It provides automated material handling, eliminates manual labour, reduces material loss, maintains dust-free environments, and ensures precise batch formulations. This results in improved safety, consistent product quality, reduced waste, and enhanced overall productivity.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.