Pneumatic Conveyor For Chemical

- Home

- Industries

- Chemical

Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

Frequently Asked Questions

Pneumatic conveying for The Chemical Industry

The chemical industry is a crucial sector that manufactures a wide range of products, from raw materials to advanced chemicals. It encompasses the production of essential goods such as fertilisers, pharmaceuticals, plastics, and industrial chemicals, playing a vital role in global economies by driving innovation and supporting various industries.

Pneumatic conveying in the chemical industry involves transporting powders, granules, and other bulk materials using air pressure or vacuum systems. It’s an efficient, dust-free method for moving materials through pipes, ensuring safe and controlled transfer while maintaining product integrity. This technology is vital for automation and optimising production processes.

A] Materials Conveyed in the Chemical Industry

As we know, the chemical industry handles a wide range of solid bulk materials, including powders, granules, pellets, fibres, and crystals, in its day-to-day operations. Managing these materials presents several challenges, as they may possess hazardous properties, pose explosion risks, or present safety concerns for personnel. Macawber has extensive experience in safely handling various powders, as demonstrated by the following list of materials we have successfully managed:

- Aluminium Fluoride

- Boric Acid

- Carbon Black

- Catalyst powder

- CPC Blue

- CPC Green

- CPVC resin powder

- Diammono Stilbene Disulphonic Acid

- Dry leach mud

- Food grade silica

- Ground chrome ore

- HMBT Powder

- Ice flakes

- Lime Powder

- Sulphur Powder

- Mancozeb

- Microcrystalline cellulose

- Optical Brightener

- P.E.S Cake

- Potassium Chloride

- Precipitated silica

- Hexamine powder

- China Clay powder

- Soap noodles

- Soda ash

- Sodium Tri Polyphosphate

- Tyre grade silica

- Urea granules

- Ground Pet coal

- Calcined petroleum coke

- Metallurgical coke

- Calcium Carbonate

- Carbomill Soda

- Dolomite

- Fertilizer powder

- HA20

- STTP

- Frisis

- Feldspar

- Micronised alumina

- Salt

- sodium tripolyphosphate

- Zeolite

Discover Macawber’s tailored pneumatic conveying solutions for the chemical industry.

B] Solutions offered by Macawber

- Dense phase pneumatic conveying for chemicals:

With a long-standing legacy in pneumatic conveying, Macawber has provided the chemical industry with Dense Phase Pneumatic Conveying systems, ranging from 0.25 TPH to 25 TPH capacity. We have supplied hundreds of conveying vessels such as Denseveyor, Ashveyor, and Variflo, addressing the needs of chemical industry clients for transporting heavy, abrasive materials over distances of 20 to 200 meters.

- Lean phase pneumatic conveying system:

For applications where material properties and high process temperatures are a concern, Macawber has assisted clients with Lean Phase Pneumatic Conveying solutions, whether positive pressure or negative suction systems are required. One notable project includes the supply of a unique mobile suction system for a graphite electrode manufacturer in India.

- High-pressure injection solution:

Macawber has demonstrated its expertise by delivering high-pressure injection systems for pulverised coal and char injection into reactors at 20 bar. Our Controlveyor system is the core of these installations, showcasing our capability to handle such complex applications.

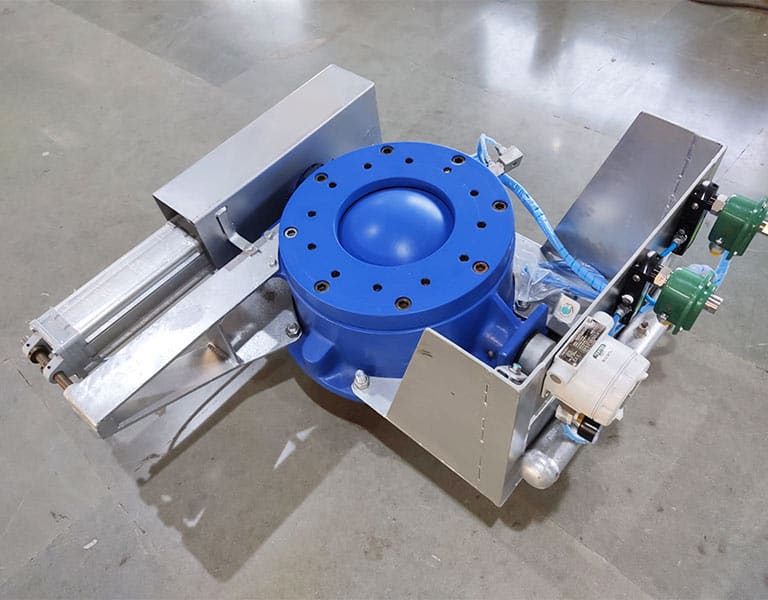

- Dome Valve:

As the original patent holder of the dome valve, Macawber proudly offers the latest generation of this valve, ensuring exceptional performance in chemical industry applications. Our dome valves are widely used in continuous and rotary vacuum dryers and can be adapted for bulk handling applications, whether under positive pressure or full vacuum conditions.

- Nitrogen-assisted pneumatic conveying solutions:

For handling hazardous and explosion-prone materials, Macawber provides nitrogen-assisted pneumatic conveying systems. These systems use nitrogen as a conveying medium, ensuring safe, reliable, and efficient material transport while minimising risks to operators and equipment.

- De-dusting system:

Macawber India offers a comprehensive range of dust extraction solutions, including bin vent filters and bag filters with suction ducts. Our tailored systems ensure optimal performance, maintaining a clean and safe environment while efficiently handling dust and particulate matter in chemical industry operations.

- Automation:

Macawber’s automated pneumatic conveying systems for chemicals enhance operational efficiency, accuracy, and safety. By integrating sensors, controls, and real-time monitoring, we optimise material flow, reduce human intervention, and ensure precise delivery while minimising downtime and improving overall reliability.

C] Macawber Products Supplied

- Denseveyor

- Ashveyor

- Variflo

- Controlveyor

- Dome valves

- Diverter valves

- Bag filters

- DV-type Diverter valve

- Loss in Weigh feeders

- Wear-resistant bends

- Bin vent filters

Unique Selling Points (USPs) of Our Design

- ASME Compliance: Macawber emphasises ASME standards when designing pressure vessels for pneumatic dense-phase conveying, ensuring safety, efficiency, and compliance. Adhering to specific codes and guidelines guarantees reliable operation.

- Dome Valves with Hard Coating: The dome valve, crucial for regulating bulk powder flow, is the most wear-prone component. Macawber’s dome valves feature special hard coatings tailored to material properties and customer requirements, including ceramic, tungsten carbide, and frit coatings.

- Heavy-Duty Design for Long Life: Macawber’s pneumatic conveying systems have been successfully supplied over the past 30 years across the Indian cement industry, thanks to a focus on heavy-duty design that results in extended equipment lifespan.

- Corrosion Allowance: Sufficient corrosion allowance as part of the design to ensure long life while handling corrosive & caustic salts part of chemical industries.

- Lined Pipes and Bends: Given the abrasive nature of bulk powders like lime, cement, additives & different dust, Macawber offers lined pipes and bends tailored to application specifics, reducing wear and tear on these components.

- Optimal Sizing Design: Based on the required conveying capacity and corresponding air requirements, Macawber optimises vessel and pipeline sizes to meet critical performance parameters and energy efficiency.

- Healthy Filtration Area: Proper venting of air is essential before material is dropped at reception points. An inadequate filtration area can lead to back pressure and system malfunctions. Macawber prioritises a healthy filtration area for efficient venting.

- Accurate Weigh Feeders: Macawber’s weigh feeders ensure precise material dosing at the right times during the steelmaking process, optimising the chemical composition of the final steel product.

As the best pneumatic conveying systems manufacturer in India, Macawber Engineering Systems India guarantees a plethora of perks when you install our equipment in your facilities. Get in touch with us right away to learn more about our pneumatic conveyor for the chemical industry!

Discover Macawber’s tailored pneumatic conveying solutions for the chemical industry.

Frequently Asked Questions

Pneumatic conveying is preferred in the chemical industry for its ability to handle hazardous, sensitive, or fine materials in a safe, dust-free, and efficient manner.

The chemical industry commonly uses dilute phase systems for lightweight materials and dense phase systems for fragile or abrasive substances requiring gentle transport.

Materials such as aluminium fluoride, boric acid, carbon black, catalyst powder, PC blue, CPC green, CPVC resin powder, and more are commonly transported using pneumatic conveying systems.

Pneumatic conveying reduces material waste, minimises emissions, and enhances energy efficiency, supporting cleaner and more sustainable operations in the chemical industry.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.