Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

India’s refractory market is picking up momentum as the demand from the steel, cement, non-ferrous metals, and glass industries is continuously increasing. Indian companies are investing heavily in R&D, advanced processing technology, and expanding capacities to make their refractories globally competitive with a market that demands quality refractories with energy-saving capabilities.

Pneumatic conveying plays a pivotal role in pneumatic conveying for refractory, allowing for clean and efficient transfer of refractory materials, alumina, silica, magnesite, dolomite, graphite, and intricate binder matrices. Pneumatic conveying minimises dust, eliminates manual transfer, increases process reliability, and facilitates continuous processing, a requirement in today’s modern refractory plants.

Explore Custom Pneumatic Conveying Solutions for Refractory Plants

Bulk Materials Handled

- Dry fine powder, granular powder

- Good flowability

- Abrasive in nature

- Moderately powdery

Refractory manufacturing involves the need to handle the powder, granule, and premixture materials from unloading the raw material to the kiln feeding process. The handling equipment has to conserve the material through complex process routes involving various silos.

Dense phase conveying is most suitable for abrasive materials with a high bulk density, as in the case of alumina powder, as well as materials like magnesite. Well-designed refractory powder conveying systems make dust-free transfer possible, which is further strengthened by strict quality control and safety standards at the plant site.

Solutions Provided by Macawber

The Dense-Phase Pneumatic Conveying

Refractory materials are generally the most abrasion-intensive. Thus, Macawber’s low-velocity dense-phase pneumatic conveying systems are an established solution for the handling of refractory materials.

These refractory material pneumatic conveying systems are designed to handle the materials at a low velocity and in a slug mode, which reduces the abrasion effect on the pipes and minimises dust emissions and velocities that could result in a flow breakdown for the difficult-to-handle materials. Macawber’s denseveyor systems, ranging from 1TPH to 20TPH, are specially designed to suit the plant layout and distances.

Lean-Phase Pneumatic Conveying

Macawber also provides lean-phase pneumatic conveying systems operations for lighter refractory parts and processed powders where a higher throughput conveyance is needed.

These high-speed systems are ideal for the transportation of fine powders and free-flowing granular material, where material degradation is less of an issue and can often complement the existing dense phase lines.

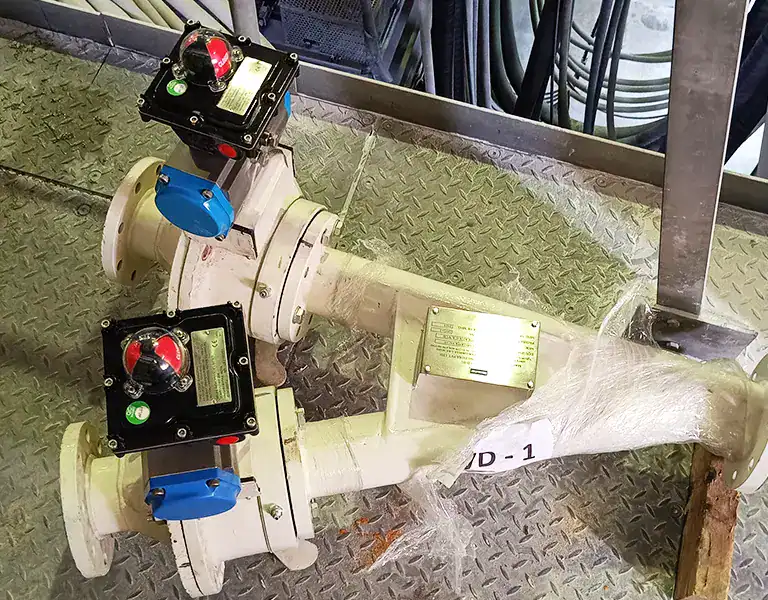

Multi-Port Diverter Valves

Macawber Engineering’s diverter valves, including pivot-type and linear multi-port designs, route abrasive material pneumatic conveying streams from single source lines to multiple destination silos. Available in horizontal and vertical configurations, these compact valves simplify complex routing, while inflatable seal technology provides a positive pressure lock, handling the most aggressive refractory formulations.

Mechanical Conveying Integration

Supporting pneumatic systems, Macawber integrates belt conveyors, bucket elevators, skip hoists, and shuttle conveyors within comprehensive refractory raw material handling systems. These mechanical components ensure precise recipe delivery across large silo banks, while specialised unloaders handle bag and drum inputs feeding into primary pneumatic circuits.

De-Dusting & Filtration

Dedusting in the refractory industry is essential to control airborne fines generated during crushing, screening, mixing, and material transfer. Efficient dust collection systems improve air quality, protect worker health, prevent contamination of refractory batches, and maintain cleaner, safer, and compliant plant operations.

Plant Automation

Macawber integrates sensors, PLC controls, and SCADA monitoring within automated pneumatic conveying systems for refractory plants, optimising flow rates, tracking inventory levels, and minimising operator intervention across complete material circuits from truck unloading through final batch delivery.

Products Deployed in Refractory Applications

- Denseveyor transporters form the backbone of abrasive material pneumatic conveying circuits, handling alumina, magnesite, and speciality refractory mixes.

- Dome valves with ceramic/tungsten carbide coatings regulate flow from pressure vessels.

- Diverter valves route materials between multiple silos/process lines.

- Bag filters provide dust collection at transfer points and silo vents.

- Wear-resistant pipeline bends engineered for extended life with abrasive material pneumatic conveying.

- DV-type diverter valves for high-pressure dense-phase circuits.

- Weigh feeders and screw conveyors for precise batch proportioning.

- Mechanical conveyors (belt, bucket elevator, skip hoist, shuttle) supporting pneumatic transfer.

Optimise Your Refractory Material Handling with Proven Technology

Engineering Advantages for Refractory Duty

ASME Pressure Vessel Design

Macawber adheres to ASME codes when fabricating vessels for dense phase circuits, ensuring safe operation with refractory dusts under cyclic pressure loading.

Wear-Resistant Valve Coatings

Dome valves receive application-specific hardfacings, ceramic for fine alumina and tungsten carbide for coarse magnesite, extending maintenance intervals in dense phase conveying for refractory materials service.

Optimised System Sizing

Vessel and pipeline dimensions get calibrated to exact capacity/airflow requirements of alumina powder conveying systems, balancing capital investment against energy efficiency and throughput targets.

Generous Filtration Design

Macawber specifies filtration areas exceeding minimum requirements, preventing backpressure that disrupts refractory powder conveying system performance during rapid vessel discharge cycles.

As a pneumatic conveying system manufacturer and supplier with thirty years of serving abrasive materials sectors, Macawber delivers field-proven custom-engineered conveying systems for refractory materials engineered for the harshest process conditions while maintaining the operational reliability expected by leading refractory producers.

FAQ's

Dense-phase pneumatic conveying systems operate at low velocities to minimise pipeline erosion and material degradation, making them ideal for handling highly abrasive refractory powders while extending equipment life.

Enclosed refractory powder conveying systems with integrated bag filters and proper sealing at all transfer points eliminate airborne dust and prevent material loss during pneumatic transfer operations.

Dense phase conveying for refractory materials provides gentle, low-velocity transport that preserves particle integrity and reduces wear for materials like alumina, magnesia, and silica.

Yes. Macawber's automated pneumatic conveying systems for refractory plants seamlessly integrate with existing batching, weighing, and mixing equipment through PLC controls and precise inventory tracking for streamlined production flow.

Test your material samples for abrasiveness, flowability, and bulk density. Match throughput needs and plant layout to select dense phase for abrasive materials or lean phase for free-flowing powders.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.