How to Choose

- Home

- How to Choose

Selection of Pneumatic Conveying System

Types of Pneumatic Conveying Regimes:

Macawber India has solutions for all your pneumatic conveying requirements and with vast expertise in all regimes of pneumatic transport with proven technologies, we offer the following solutions:

| Regime Parameters | Lean, Dilute Phase | Medium Phase | Pulse Phase, Pulse Flow | Solid Dense Phase | Discontinuous Dense Phase | Continuous Dense Phase | Vacuum Dense Phase |

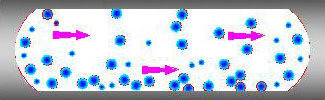

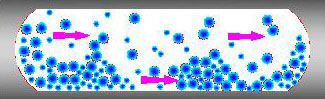

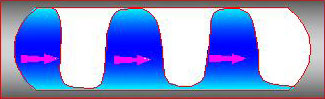

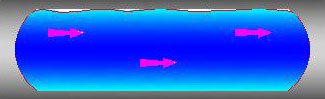

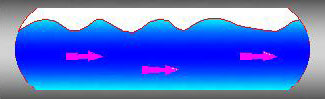

| Graphical Rep (Longitudinal) |  |

|

|

|

|

|

|

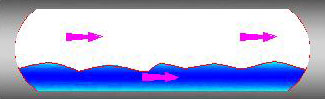

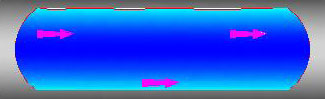

| Graphical Rep (Cross Section) |  |

|

|

|

|

|

|

| Air Volume | Extremely high | Very High | Moderate | Extremely low | Very low | Moderate | Very low |

| Wear & Tear | Extremely high | Moderate | Extremely low | Very low | Extremely low | ||

| Power Consumption | Extremely high | Very High | Moderate | Extremely low | Very low | Moderate | Very low |

| Macawber Technology | Dilute phase | Pulseveyor | Denseveyor | Denseveyor, Ashveyor | Variflo, Macpump | Compact Powder Transfer System | |

How to Choose a System:

Correct selection of a Pneumatic Conveying System is governed by the following criteria:

Material properties / characteristics:

- Particle shape

- Mean particle size

- Particle size distribution

- Moisture content

- Hygroscopic & Deliquescence

- Friable

- Adhesive-ness, Cohesive-ness, Explosive, Combustible

- Power Consumption

- Wear Tear Due to Velocity

- Segregation

- Moisture Content

- Hygroscopic & Deliquescence

- Headroom & Space Constraint

- Venting & Dusting Constraint

The choice of the right pneumatic conveying system is primarily governed by the material properties as well as the capacity and distance of conveying. For example, powders, pellets, and granules are preferably conveyed in a dense phase regime as it is optimal for these materials. Flakes are generally conveyed in the dilute phase due to their particle size and shape. Similarly, high capacities and longer distances are conveyed using dense phase systems, and conversely, low capacity, short-distance compact requirements are catered to by dilute phase systems.

Hence, the right choice of a pneumatic conveying system is best left to the experts, and rest assured, Macawber India guides you like none other!”