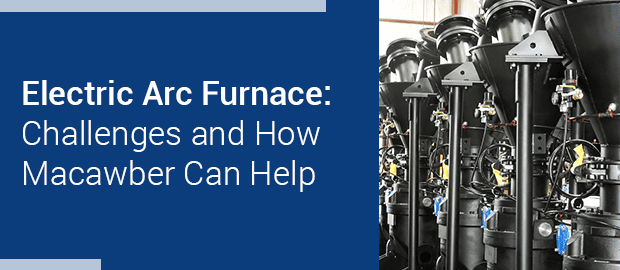

An Electric Arc Furnace is the most widely used furnace when it comes to steel production. As an efficient tool, it also helps curb the rising costs of waste disposal. In this article, we’ll check out in detail what an electric arc furnace is, the challenges of handling electric arc furnace dust and how Macawber can help.

Learn How Macawber Can Revolutionize Your Electric Arc Furnace

A] Methods of Cement Conveying

An electric arc furnace (EAF) is a furnace that heats charged materials through an electric arc for melting certain metals such as scrap steel without changing the electrochemical properties of that metal. Heating through high electric voltage currents is the primary heating element of the furnace.

EAF is the central part of the production route and is an excellent alternative to the dominant BF-BOF (Blast Furnace) route. EAF are extremely hot enclosed spaces widely used in the steel production industry. They also play a crucial role in iron & steel recycling operations and are used in mini-mills that recycle iron scrap.

These furnaces are available in varied sizes, with the smallest having a capacity of 1 tonne and the largest approx. 400 tonnes. The temperature can range between 3,000 degrees and 3,500 degrees Celcius.

Components of an Electric Arc Furnace

Powered by three graphite spikes, an electric arc furnace is like a giant heat-resistant kettle. It consists of a refractory-lined vessel with a removable water-cooled lid that holds the graphite spike and connects it to large power lines that act as electrodes.

The furnace has three parts: the shell (body), the hearth (bottom) and the roof.

- The body (shell) consists of the lower steel bowl and sidewalls.

- The bottom (hearth) contains the refractory that lines the lower bowl.

- The roof, most likely to be shaped as a section of the sphere, is either refractory-lined or water-cooled.

It is made from alumina and magnesite-chromite bricks. When the lid is lifted, the furnace can be loaded with any combination of solid fuel, iron ore, flux, or iron scrap. The electrodes can be lowered once the lid is securely closed to begin the process of melting.

B] Types of Cement Handled

The electric arc furnace process can be classified into three categories; charging the electrodes, melting the metal or ore, and refining.

- Charging the electrodes: The heavy & light scrap is first loaded into the large basket and preheated via the exhaust gas. To speed up the slag formation, burnt lime and spar are added. Next, the roof of the furnace is oscillated to charge the furnace.

- Meltdown process: This process uses electrodes that are moved down (or loaded) onto the scrap. Initially, low voltage is used. Once the electric arc is properly shielded (between the electrode and the metal) the voltage is gradually increased. This speeds up the melting process. For large arc production, low current is used, which helps minimise heat loss.

- Refining: The process of refining begins during the meltdown process itself. During the single oxidising slag, only phosphorus is removed. Whereas, in the double oxidising slag, both phosphorus and sulphur are removed. The next process is de-oxidisation, following which the molten metal is obtained.

*Post these processes, to cool down the furnace, hollow annulus spraying or tubular pressure panels are used.

Learn How Macawber Can Revolutionize Your Electric Arc Furnace

C] Advantages & Disadvantages of an Electric Arc Furnace

Advantages of an Electric Arc Furnace

- This system makes it easy to produce steel from 100% scrap metal feedstock. Compared to steel-making from ores, this process is more energy-efficient.

- As a highly efficient and flexible system, EAF is not dependent on any specific type of charge.

- The entire melting process can be automated.

- It helps produce a wide range of steel grades.

- Electric arc furnaces are easy to use and require low capital investment.

Disadvantages of an Electric Arc Furnace

- The arc could cause uneven heat distribution in the furnace.

- By reacting to the furnace gases & vapour, the arc could release large amounts of hydrogen and nitrogen.

D] Types of Electric Arc Furnaces

- Direct Arc Furnace: As the name suggests, in the direct arc furnace, the arc is in direct contact with the charge. Heat is also produced via the charge itself. Hence, the charge can be heated to the highest temperature.

- Indirect Arc Furnace: In an indirect arc furnace, an arc is formed between the two electrodes above the charge, while heat is slowly transmitted to the charge by radiation. In this type, the temperature of the charge is lower compared to the direct arc furnace.

- Submerged Arc Furnace: Submerged Arc Furnace is a cylindrical furnace. It forms an arc between the carbon electrodes (top) and the hearth electrodes (bottom). The hearth lining is made from magnesite, which is a good conductor of heat. The number of electrodes taken from the roof depends on the type of supply required.

Difference Between Direct Arc Furnace and Indirect Arc Furnace

| DIRECT ARC FURNACE | INDIRECT ARC FURNACE |

|---|---|

| Heat is subjected directly to the material | Since the arc burns above charge, it is not direct and doesn’t form a part of the electric circuit |

| Lined with acid or basic refractories, this furnace consists of a cylindrical steel shell | Lined with basic refractories, this furnace consists of a barrel-shape steel shell |

| It is used for melting alloy steels | It is suitable for melting a range of alloys, particularly copper-base alloys |

| Sizes vary from a few kilograms for laboratory units to 100 tonnes per batch | These are relatively smaller units |

| The temperature of the charge is extremely high | Temperature of the charge is lower compared to a direct arc furnace |

| The current that passes through the charge develops an electromagnetic field. Thus, necessary stirring action is automatically obtained by it | There is no stirring action as the furnace is rocked mechanically |

| It is generally used for steel production | It is used for melting of non-ferrous metals such as brass, copper, etc. |

| It operates on a high tension three-phase power supply | It operates on a single-phase power supply |

Challenges in Handling EAF Dust

- The electric arc furnace dust is generated in a combustion process and contain hazardous materials such as lead, cadmium, zinc, etc. These hazardous materials require reliable methods for conveying and disposing of. They are also highly abrasive and may contain high moisture content.

- The EAF dust has limited reuse due to its high zinc content. Also, the non-ferrous metals present in the EAF dust can prove to be hazardous to human health and the environment.

- The steam produced by the EAF dust is also considered dangerous as it can leach into the ground and contaminate the groundwater.

Learn How Macawber Can Revolutionize Your Electric Arc Furnace

How Can Macawber Help?

The most appropriate way to convey EAF dust is through dense-phase pneumatic conveying that holds the ability to convey EAF dust reliably with an added advantage of less pipe wear and tear. Macawber has been working with multiple steel industries for several years, providing the best pneumatic conveying solutions to effectively manage electric arc furnace dust.

Denseveyor – Multi Denseveyor System

This is a dense-phase pneumatic system used for conveying hot, abrasive and wet materials. Some of the features of Denseveyor are as follows:

- It is used to convey material without segregation of blended materials.

- It can handle 400 deg. C temperature.

- It is fully enclosed, dust-free, power-efficient and built to last.

- It is capable of achieving very high phase densities.

Need help selecting the right pneumatic conveying system for your application? Send us your requirements now!

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.