Discontinuous Dense Phase System for Optical Brightener

- Home

- Case Study

- Discontinuous Dense Phase System for Optical Brightener

Discontinuous Dense Phase System for Optical Brightener

Overview of the Client

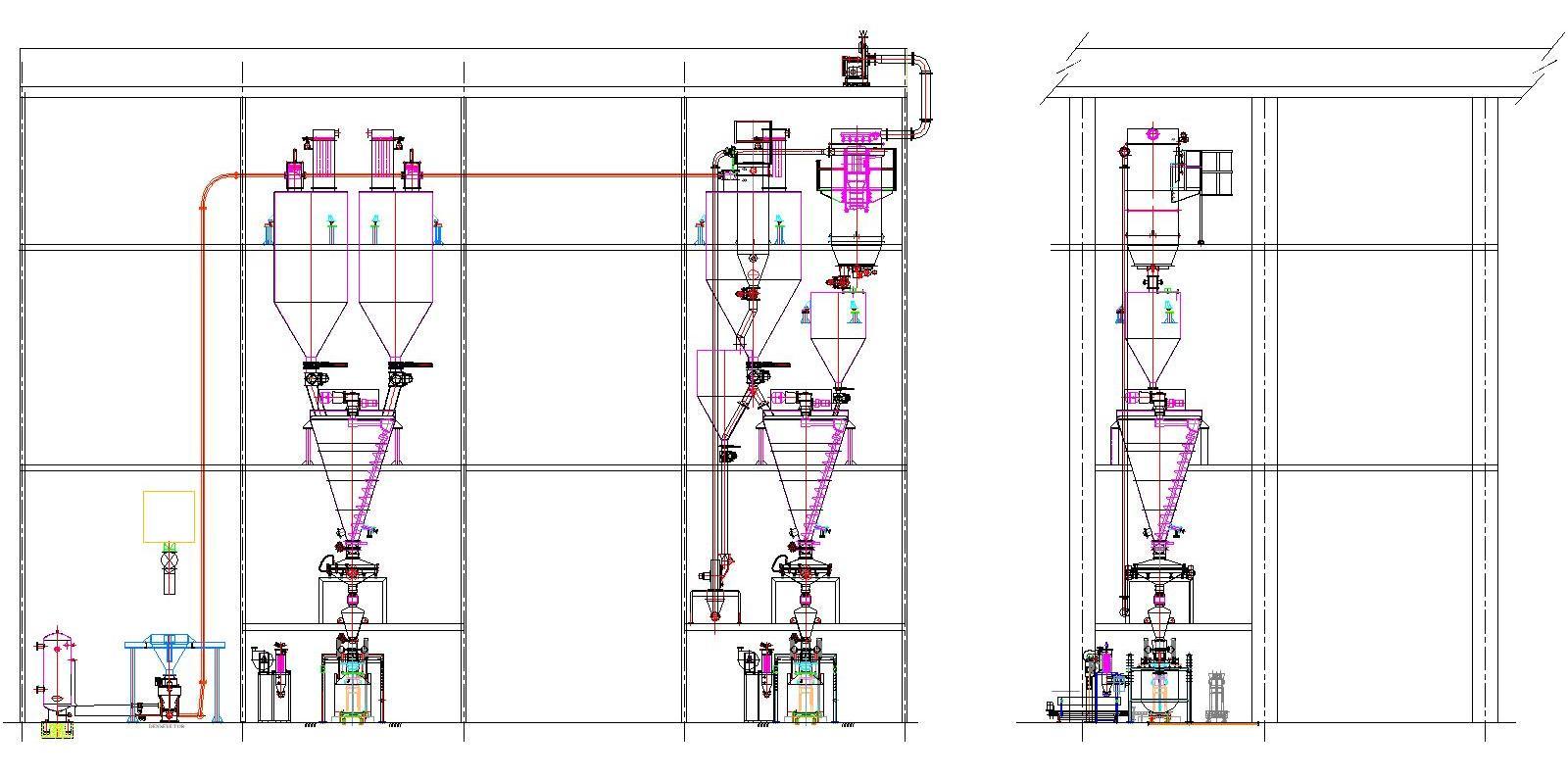

The following case study highlights Macawber India, the leading pneumatic conveying system manufacturer that delivered a specialised dense-phase pneumatic conveying systems solution by utilising Denseveyor for optical brightener. This fine, ultra-light, dust-prone powder is usually used in whitening and brightening applications, hence necessitating gentle conveying to avoid aeration, segregation, and degradation. The system follows through with product integrity from surge hopper collection via silos, mixing, sieving, and bagging.

Why Macawber India was Called Upon

Macawber India was chosen to design a custom dense phase pneumatic conveying systems configuration utilising the proven & reliable denseveyor, for controlled conveying of this powdery material. Dust-free handling with consistent flow and minimum degradation was the goal, from surge hopper collection through silo storage, mixing, and onto bagging. This met the requirement for low-velocity transportation to preserve the brightness characteristics of the powder.

The Problem We Had to Solve

The extremely fine, powdery nature of the optical brightener made the material highly susceptible to aeration, segregation, and degradation in conventional high-velocity pneumatic systems, where loss of critical brightness properties might occur. Precise routing from a surge hopper into three storage silos via diverting valves and a terminal box was required, enabling flexible recipe-driven batching with accurate weighing.

Added challenges were the need for long-distance conveyance – 40 m horizontal, 20 m vertical – the integration of gentle Nauta mixing, Vibro sieving to remove oversize, magnetic separation for contaminants, and dust-free transfer to bagging, while maintaining complete automation, minimum wear, and superior pollution control.

Solutions We Provided

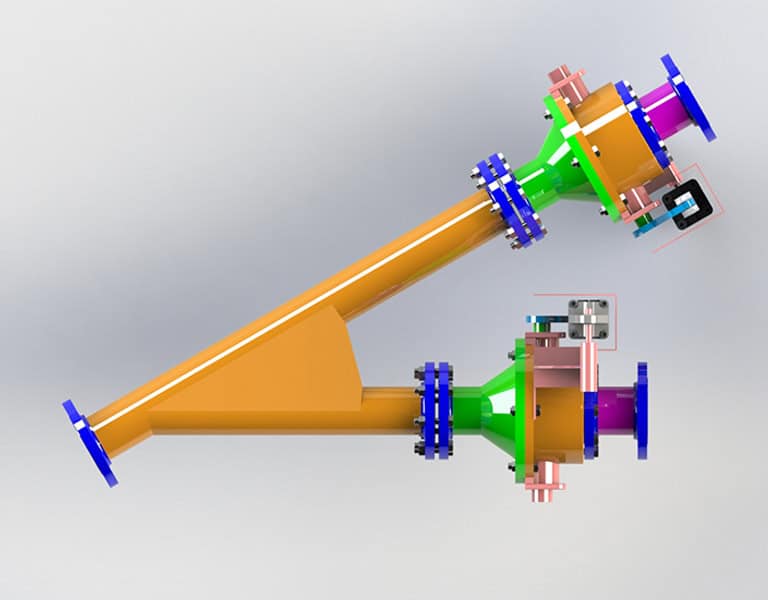

Macawber India used its dependable 3/8 denseveyor, a compact, dense-phase vessel, to transport optical brightener from the surge hopper to three storage silos via diverting dump valves and a terminal box. After weighing for recipe-driven batching, the vessel feeds a Nauta mixer for light, uniform blending. The material then passes through a Vibro sieve to eliminate oversize particles and a magnetic separator to remove contaminants before bagging, with SS 304/316 construction ensuring high-purity, dust-free output.

System Advantages

- Reduced labour due to complete automation and SCADA control.

- Eliminated bulkers, cutting hiring costs.

- Minimal downtime during maintenance.

- No spillage with built-in pollution control dedusting.

- Low wear on pipeline, system, and material.

- The capacity exceeded the specification of 1 TPH.

Result

Dust-free operation, superior product protection, and increased efficiency were provided by the dense-phase pneumatic conveying systems supplied by Macawber India. The system ensured consistent flow, accurate batching, and operational reliability throughout the process.

Project Summary Table

| Property | Details |

|---|---|

| Material | Optical Brightener |

| Temperature | Ambient / 30 to 50 deg C |

| Bulk Density | 0.5 T/M3 |

| Particle Size | 100-300 microns |

| Characteristics | Very fine, powdery, dusty & fairly good flowability |

| Property | Details |

|---|---|

| Feed Point | 1 No |

| Reception Points | 3 Nos |

| Capacity | 1 TPH |

| MOC | SS 304 for all components except pipes in SS 316 |

| Horizontal Distance | 40 m |

| Vertical Distance | 20 m |

Explore Dense Phase Pneumatic Conveying Solutions for Fragile Powders

Gallery

Get in Touch with us Today!

Containing Address

130-131, Hindustan Kohinoor Complex, LBS Road, Vikhroli-West, Mumbai - 400083.