Discontinuous Dense Phase System for Calcined Lime – Power Plant, Philippines

- Home

- Case Study

- Discontinuous Dense Phase System For Calcined Lime – Power Plant, Philippines

Discontinuous Dense Phase System For Calcined Lime – Power Plant, Philippines

Client’s Overview

Why Macawber India was Called Upon

The Problem We Had to Solve

The two primary factors were particularly challenging for us. The first one was the high conveying capacity required, and the second was the long conveying distance. To ensure consistent, dust-free, and controlled material flow over long distances demanded a robust system engineered for minimal degradation and maximum operational uptime.

Solutions We Provided

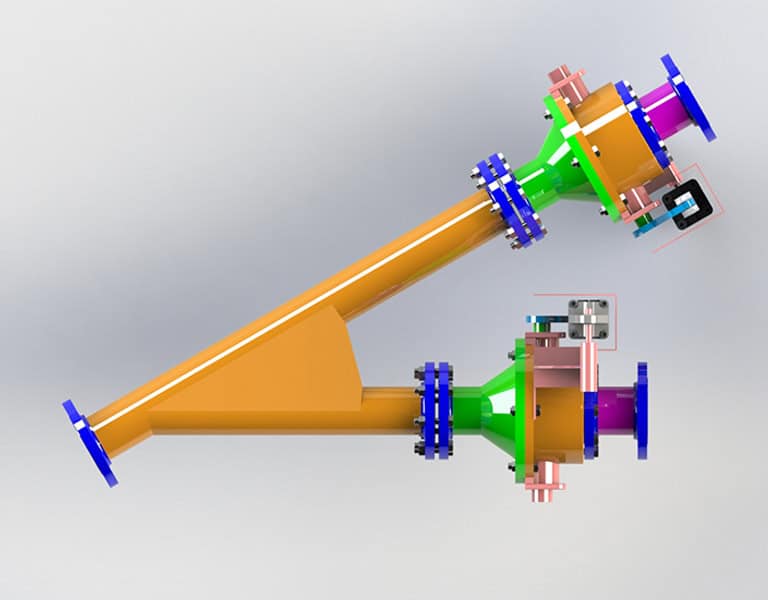

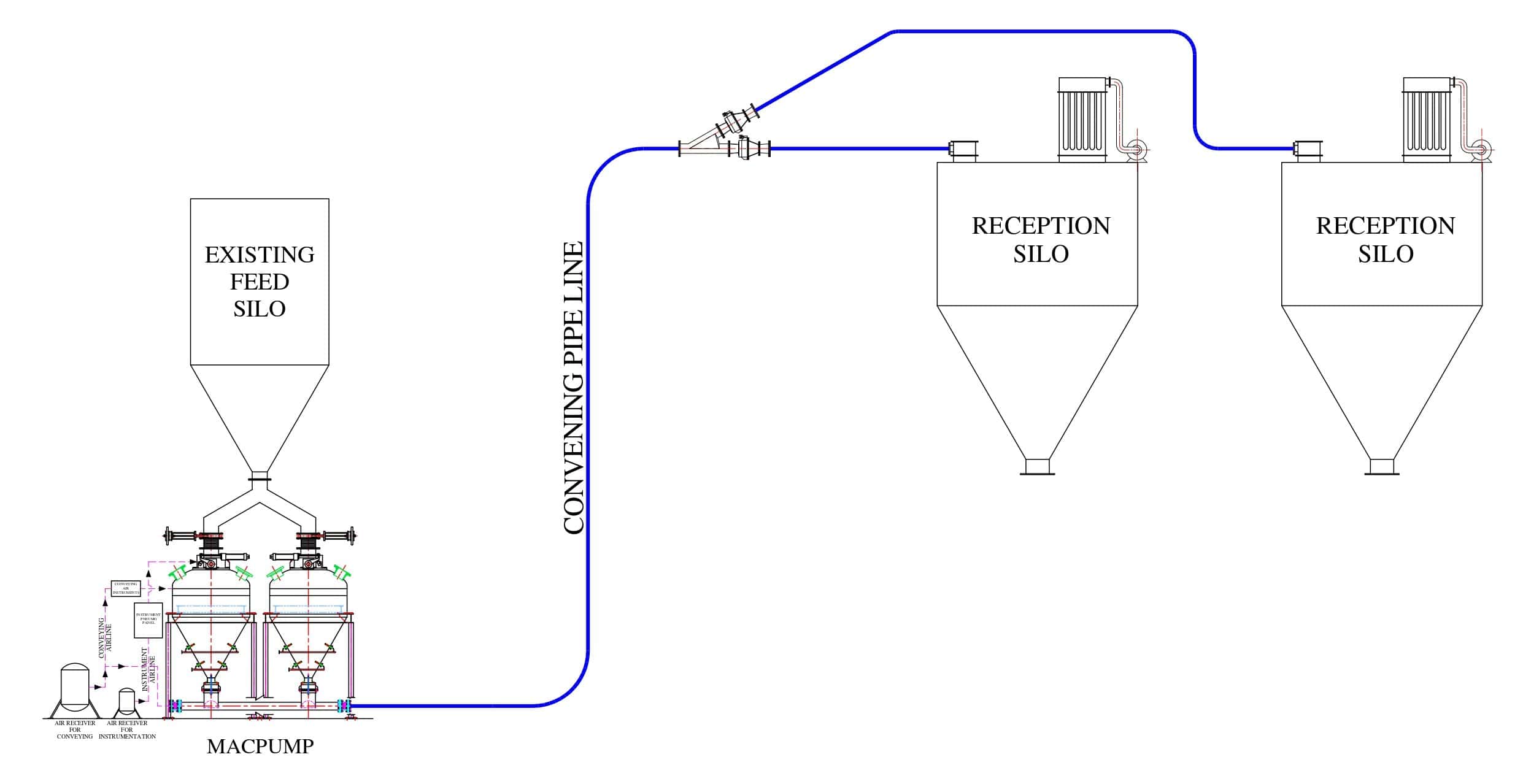

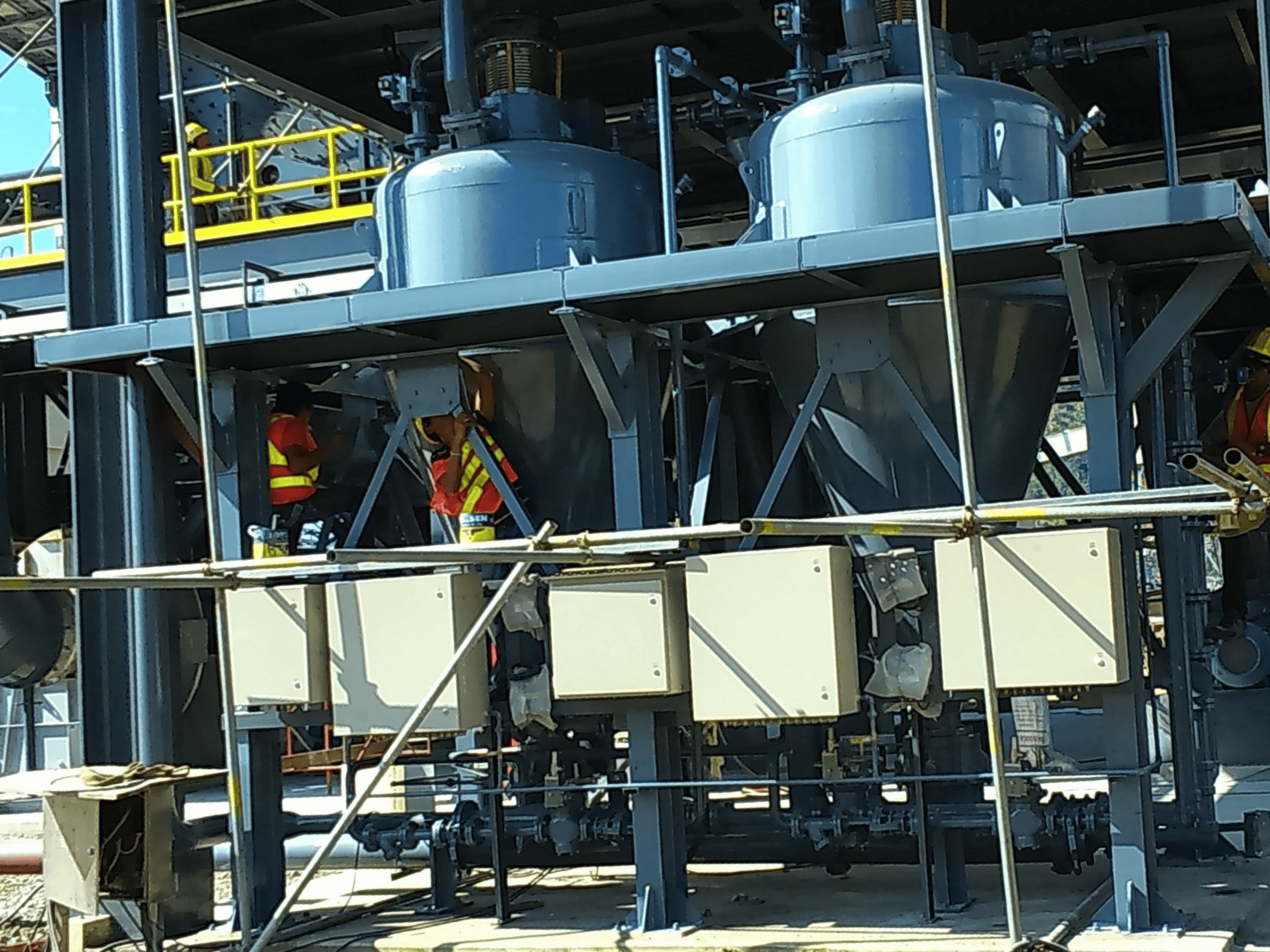

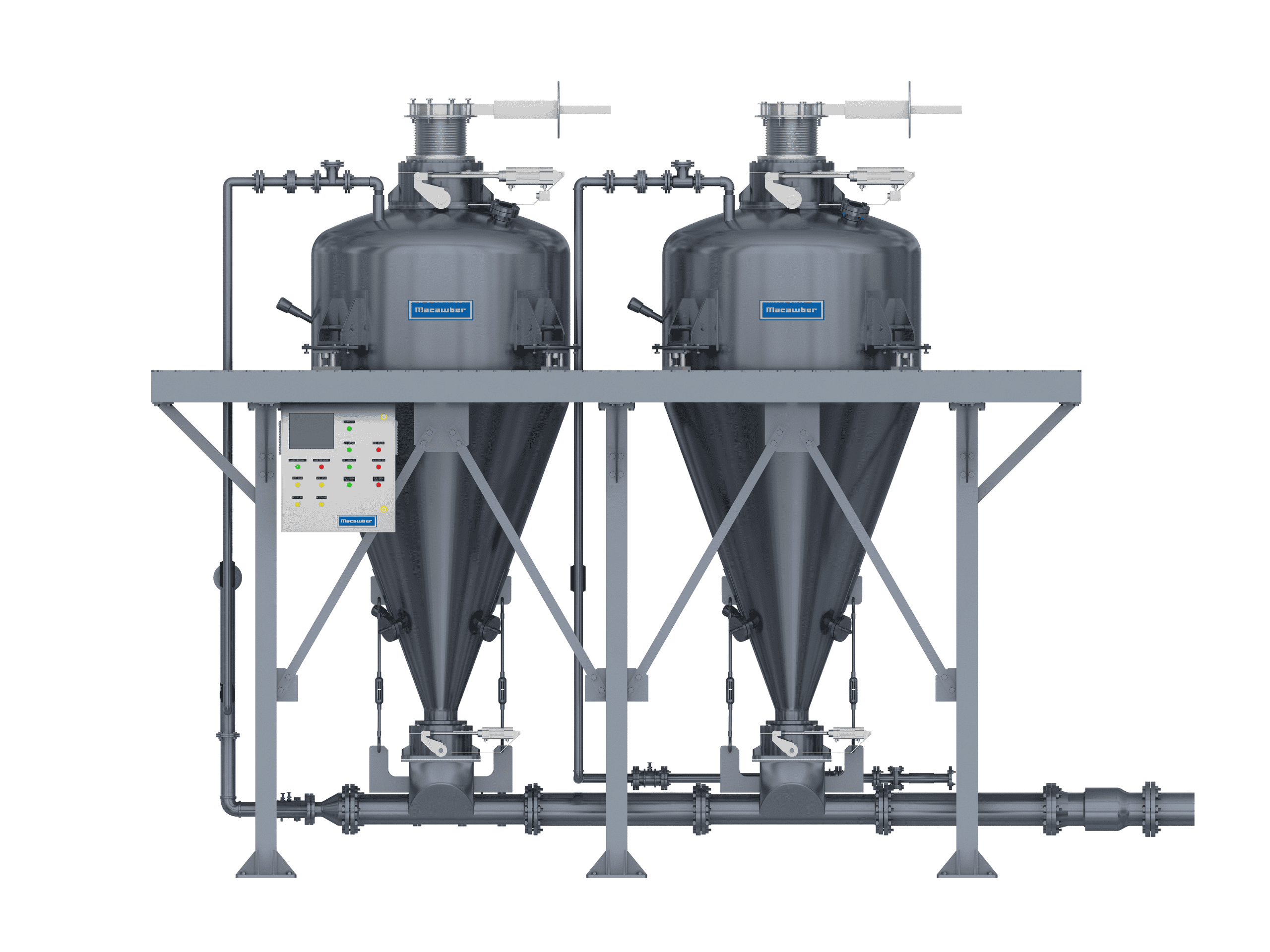

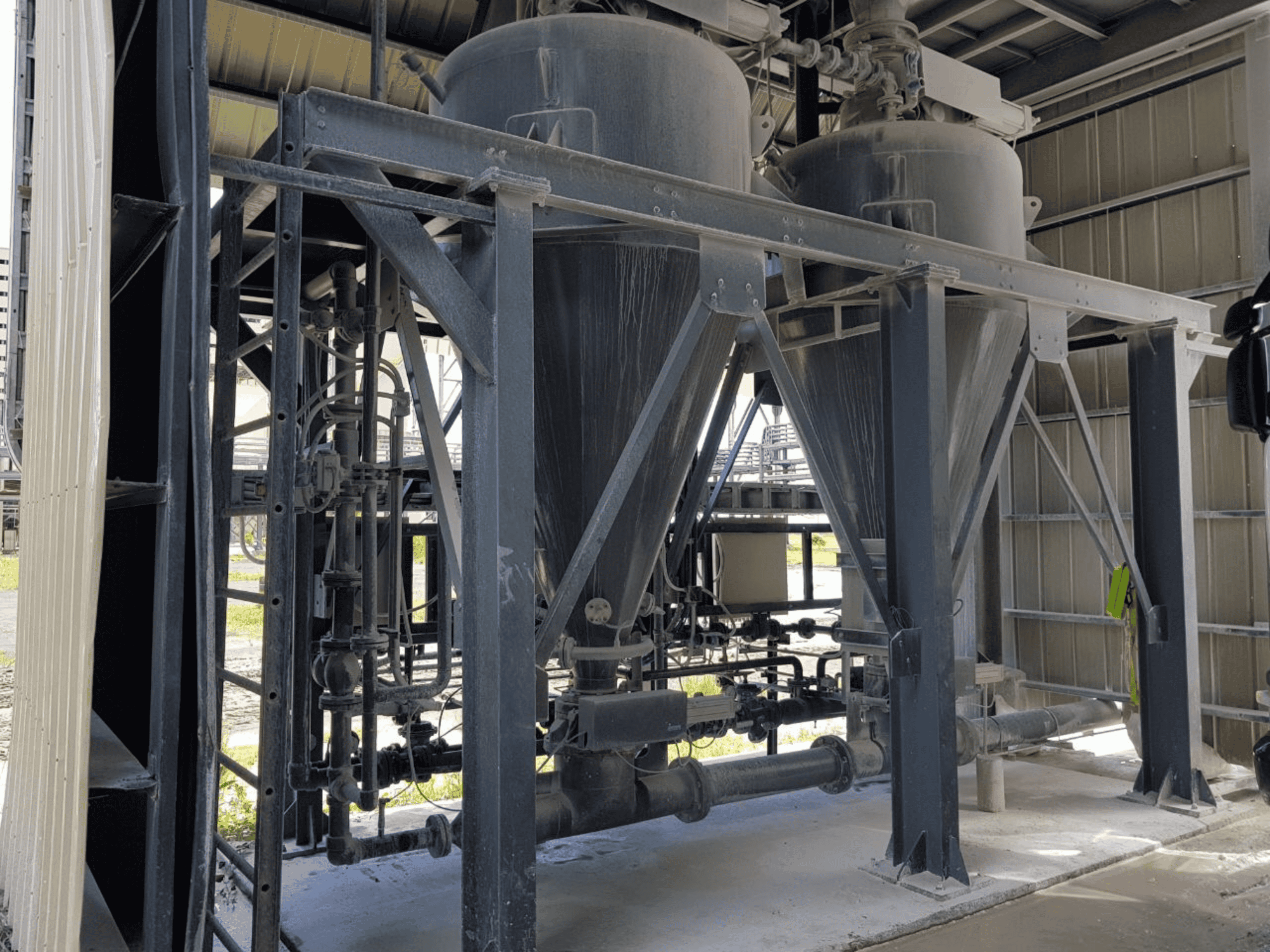

To meet the client’s expectations, Macawber India designed a customised dense-phase pneumatic conveying system equipped with twin Macpump vessels operating in tandem. This innovative configuration enabled the system to feed two separate reception points without compromising efficiency and throughput.

System Advantages

- Higher conveying capacity due to twin Macpump tandem operation.

- Reduced filling time with simultaneous filling and conveying cycles.

- Lower compressed air consumption results in reduced operating costs.

- Capability to feed two different reception points using a single system.

- Smooth, continuous, and low-velocity dense-phase material flow.

- Reliable performance over moderately long conveying distances.

- Lower maintenance needs and reduced system downtime.

- Improved process stability with consistent feeding to the raw meal kiln.

Result Time

Through our customised conveying system, the result was an increased number of conveying cycles, higher overall capacity, and smooth and uninterrupted material transfer. The solution Macawber India provided not only met the plant’s technical requirements but also enhanced operational reliability, reduced maintenance needs, and ensured stable kiln feeding.

Project Summary Table

| Material | Limestone |

|---|---|

| Temperature | Ambient |

| Bulk Density | 1000 kg/m³ |

| Particle Size | 0 to 1.8 mm |

| Characteristics | Free-flowing, abrasive, hygroscopic |

| Feed Points | 1 No |

|---|---|

| Reception Points | 2 Nos silos |

| Capacity | 60 TPH |

| Distance Horizontal | 400 M |

| Distance Vertical | 25 M |

With this project, Macawber India reinforced its position as a leading solutions provider for pneumatic conveying systems in the cement industry, demonstrating its ability to engineer systems tailored to demanding industrial environments.

Also, over the past decade, Macawber India has been a trusted partner to major cement manufacturers in the Philippines, addressing their growing needs in pneumatic conveying and bulk material handling. If you are ready to elevate your plant’s efficiency, contact us now!

Convey materials without any quality degradation with our highly efficient Dense Phase Pneumatic Conveying Systems.

Gallery

Get in Touch with us Today!

Containing Address

130-131, Hindustan Kohinoor Complex, LBS Road, Vikhroli-West, Mumbai - 400083.