Safe Handling of Coke Oven Dust with Nitrogen-Based Dense Phase Pneumatic Conveying

- Home

- Case Study

- Safe Handling of Coke Oven Dust with Nitrogen-Based Dense Phase Pneumatic Conveying

Safe Handling of Coke Oven Dust with Nitrogen-Based Dense Phase Pneumatic Conveying

Customer Requirement

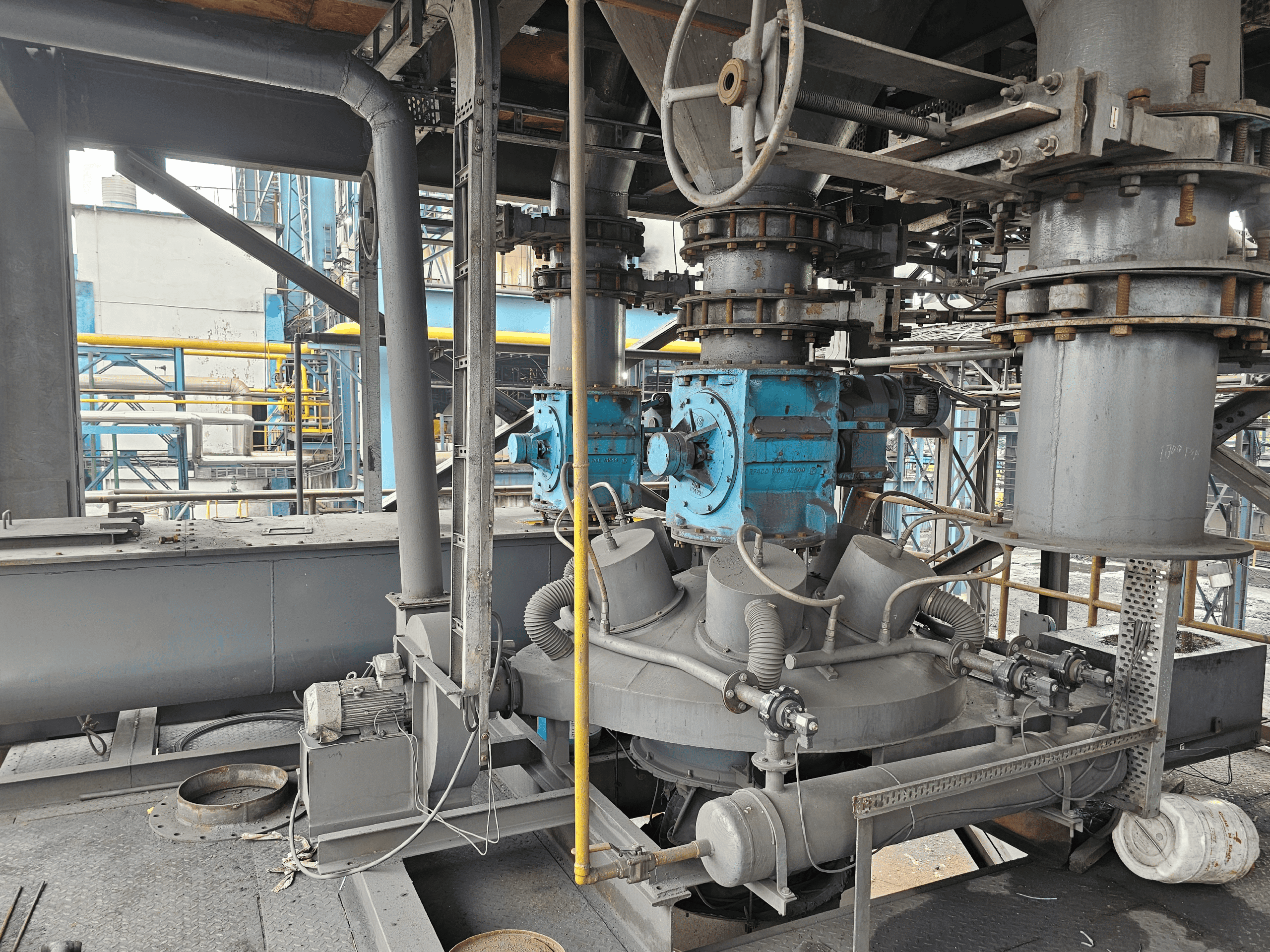

The customer required a safe and reliable coke oven dust handling solution for the dust, which accumulated in the mill fan section, and a material characterised by small particle size and abrasiveness, with the capability to explosively separate. The primary objective was to deliver continuous, dependable, and safe transport of the dust to a central collection silo with low operation expense and risk level. Moreover, the system must be very environmentally compliant by preventing fugitive dust emissions and having minimal manual operation.

The client also emphasised the importance of a solution from a reputable pneumatic conveying system manufacturer in India that would have seamless interfacing with their automation system to provide precise control and monitoring and reduce the workload of operators. The guarantee that the system would continue to be durable and reliable under round-the-clock operation was another crucial requirement.

Challenges Encountered

Coke oven dust was accompanied by a number of difficulties that needed careful engineering. It is safe, as abrasive particles can cause more wear and tear on regular conveying pipelines, resulting in regular maintenance and outages. Its pyrophoric character included the fact that even minimal contact with oxygen would lead to ignition and create a hazardous safety threat to plant staff. Moreover, the system needed to convey at a considerable distance along a combined 100 metres of horizontal and vertical movement, with the added need to control multiple feed points.

Traditional pneumatic systems were not applicable since they had the potential to cause dust re-entrainment, pipe erosion, and downtime operations. Adding dust-tight automatic control, environmental acceptability, and safe handling of materials created an added obstacle. Generally, the client required a solution that would fulfil safety, efficiency, and environmental regulation requirements simultaneously.

Solutions We Provided

- Recommended and installed a dense phase pneumatic conveying system with nitrogen, utilising a fully inert atmosphere for completely eliminating explosion risks.

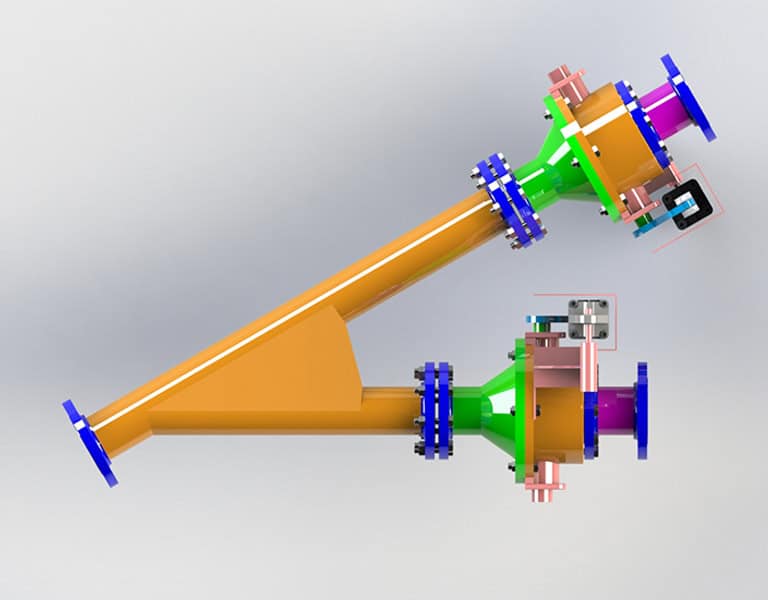

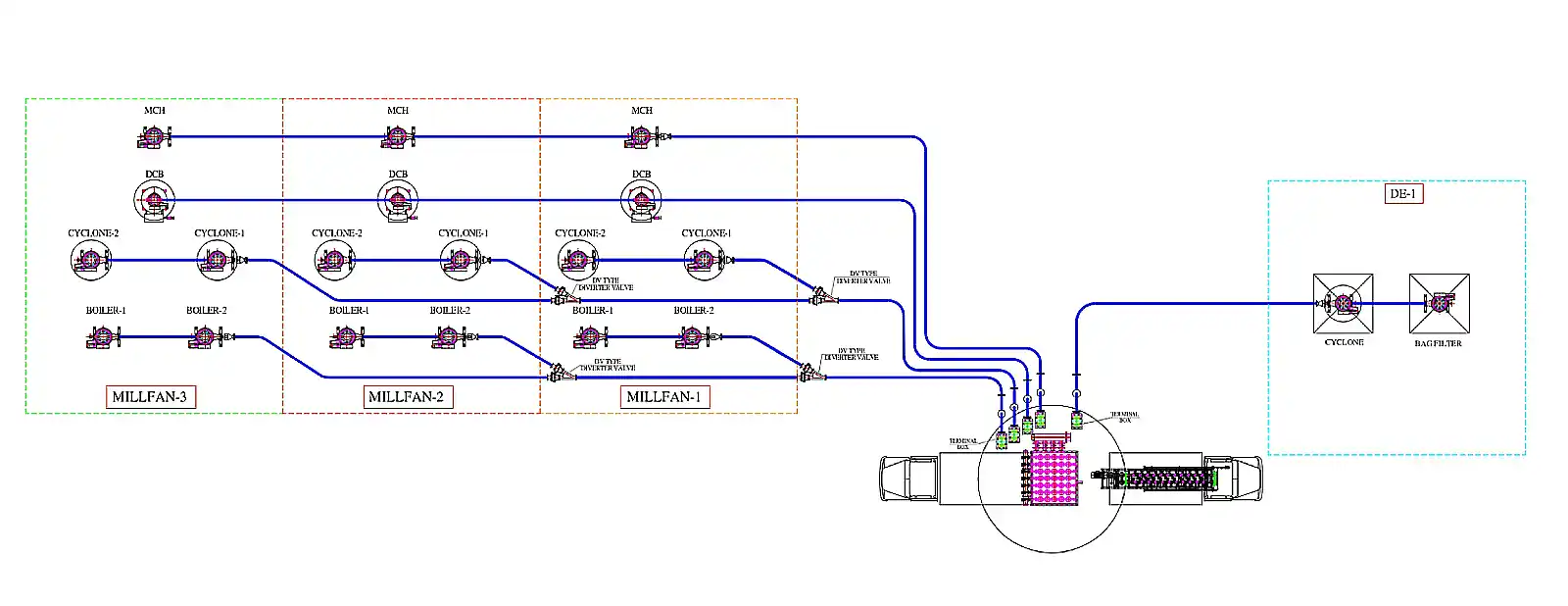

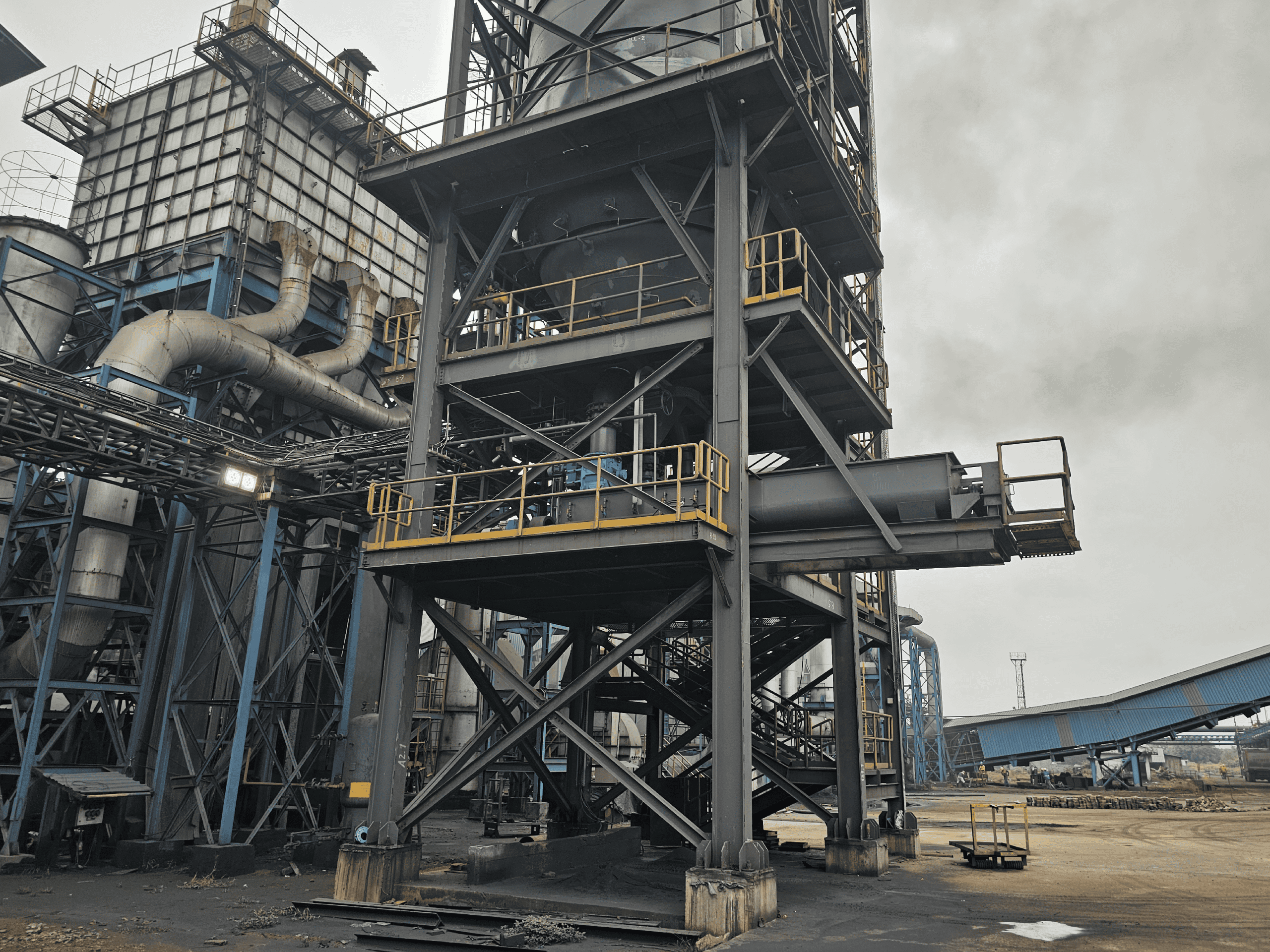

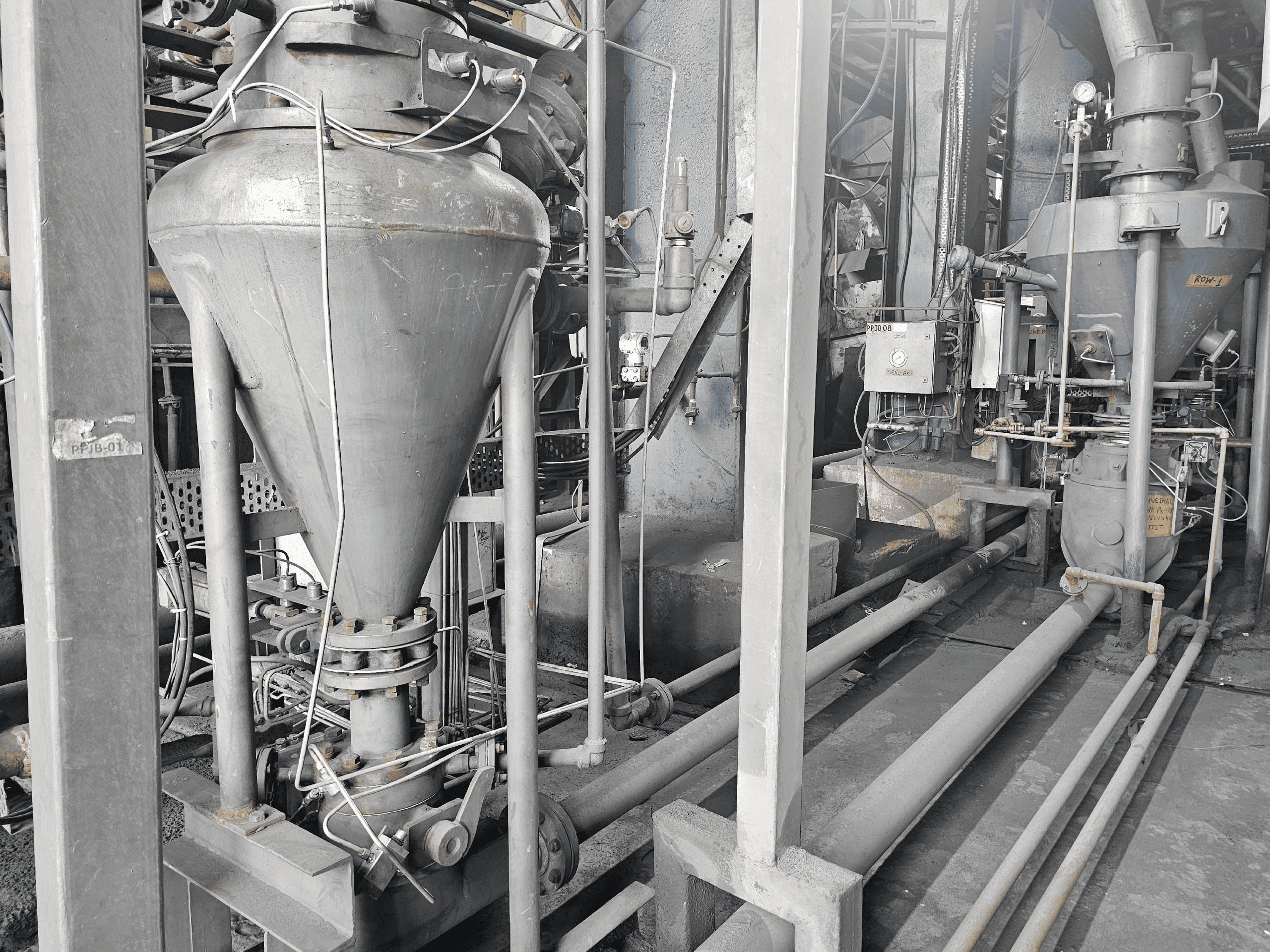

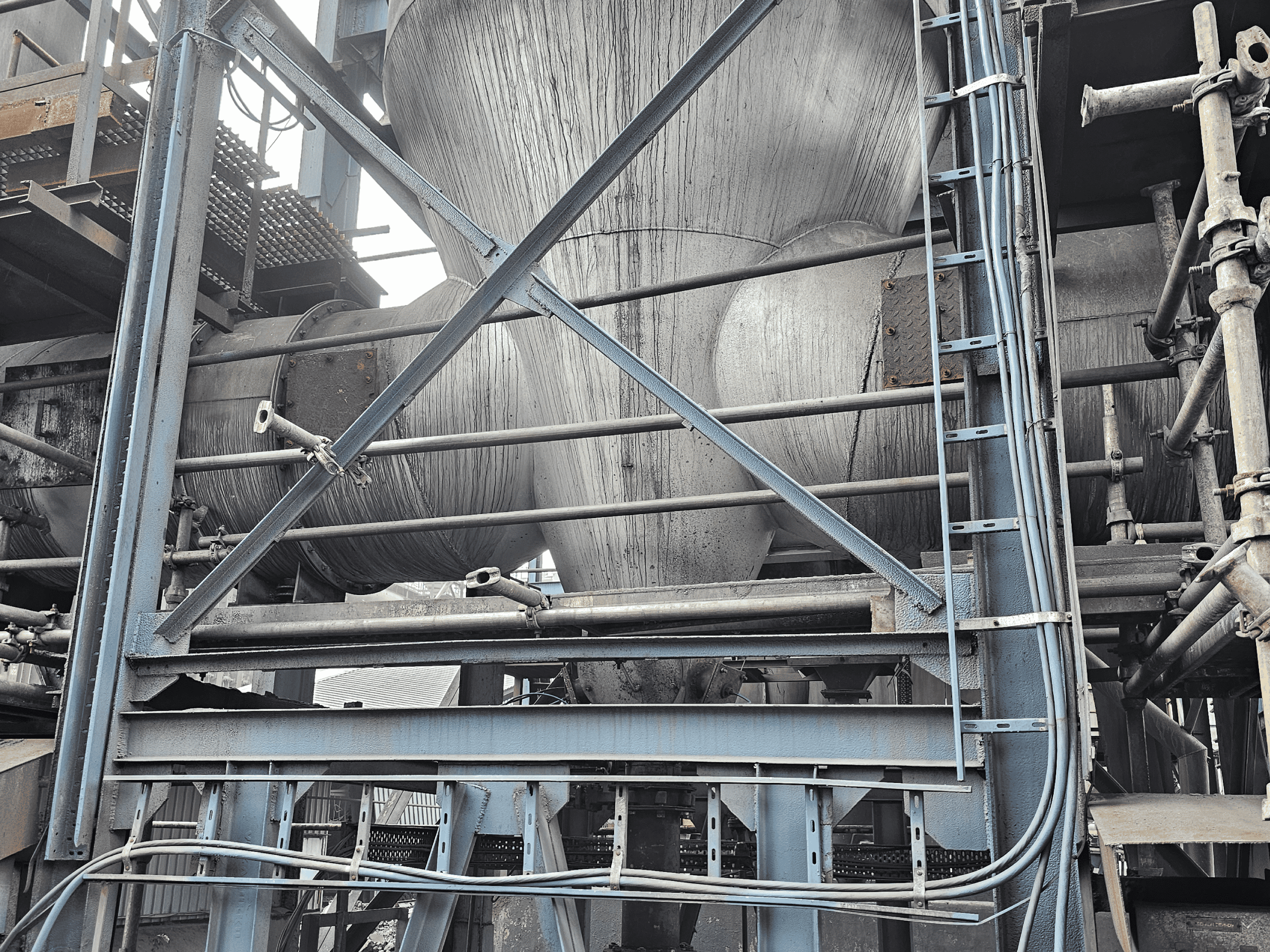

- Highlighting the Denseveyor/Ashveyor conveying vessel, supported by a battery of 20 feed points from the mill fan and dedusting units.

- Facilitated remote dust transfer over 80 metres horizontally and 20 metres vertically to a mid-reception silo.

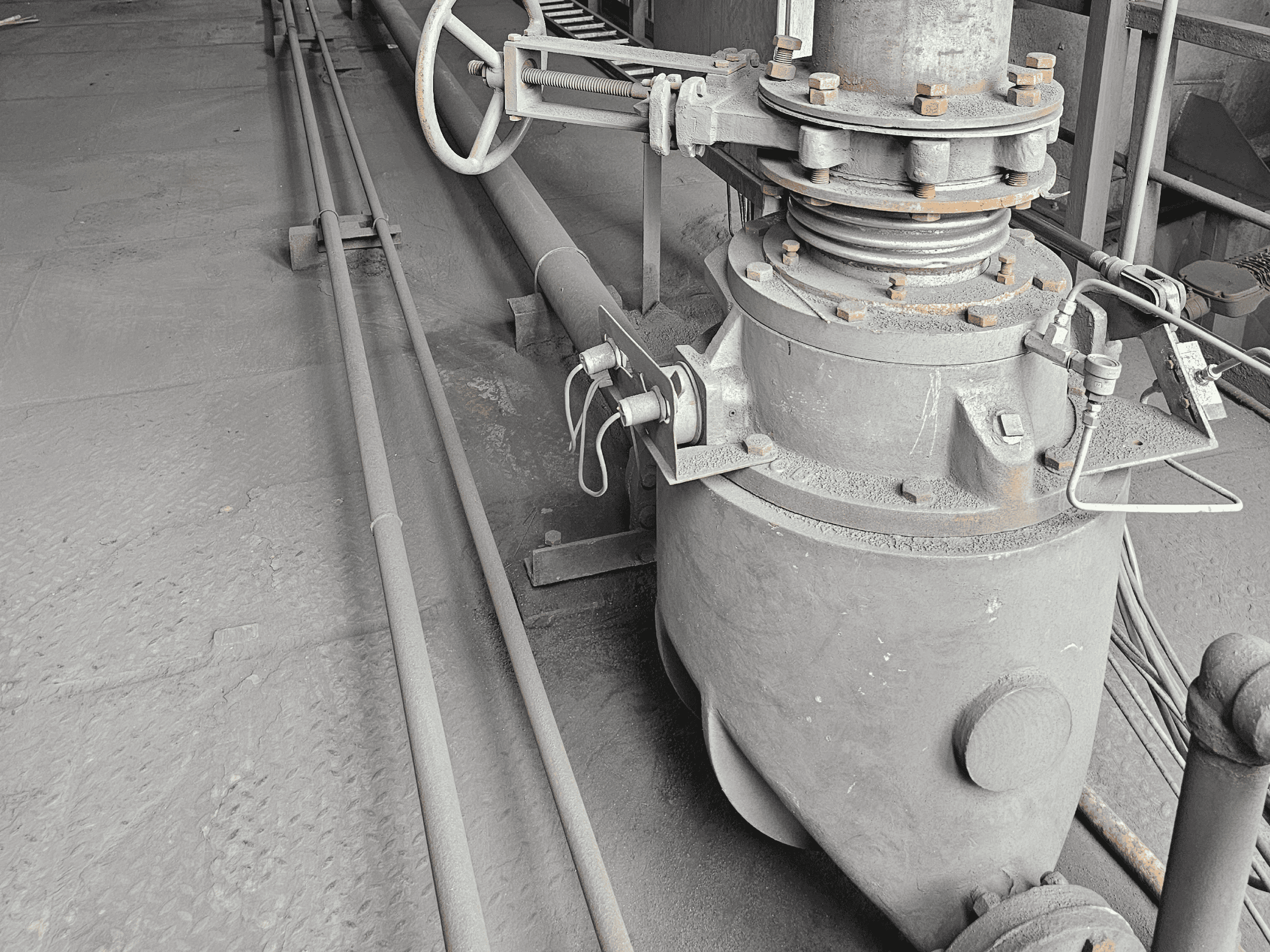

- Integrated Macawber's patented Dome Valve for dust-tight sealing under continuous use and pressurisation cycles.

- Used low-velocity dense-phase conveying, which removed pipeline wear, power consumption, and re-entrainment of dust.

- Utilised a telescopic unloading chute with a rotary paddle shaft for controlled dry dust discharge at 20 TPH capacity.

- It is seamlessly integrated into a PLC system that offers the potential to monitor and control conveying cycles and run independently.

- Combined nitrogen-based inert conveying with dense phase technology to offer a solution that optimises safety and efficiency of operations.

- Developed the abrasive and fine dust conveying system, which provided durability, stability and consistency of operation in the continuous cycles.

Results

The nitrogen-dense phase system significantly enhanced the client’s dust-handling procedure. With the supply of an inert nitrogen atmosphere, the system eliminates the explosion hazard, even during continuous operation. Dense-phase technology enabled efficient, low-speed conveying, minimising pipeline wear and energy, extending equipment life, and reducing maintenance costs. The dome valve provided settled, dust-free running with stable performance in repeated cycles of pressurisation.

The dust was transported and deposited in the middle silo over a distance of more than 100 metres with a great degree of efficiency and safety. Moreover, the closed system prevented fugitive emissions, which also made the plant safer and cleaner. The automation through PLCs minimised the role of the operator to the bare minimum, enhancing the accuracy of operations and reducing downtime.

In all, the system optimised workplace safety and process productivity and established the benchmark for processing fine, abrasive, and explosive materials like coke oven dust. By combining visionary engineering with common-sense protection benefits, Macawber Engineering delivered a device not only responsive to the client’s immediate requirement but also, in the long run, offering reliable, minimised running risks and giving plant operators a sense of security.

Project Summary Table

| Material | Coke Oven Dust |

|---|---|

| Bulk Density | 0.6 – 0.8 T/m³ |

| Particle Size | Fine |

| Temperature | 200-400 Degree C |

| Nature of Material | Fine, abrasive, explosive |

| Moisture Content | Nil |

| Pneumatic Conveying System | |

|---|---|

| Type of System | Dense Phase Pneumatic Conveying System |

| Conveying Vessel | Denseveyor/Ashveyor |

| Conveying Capacity per Point | 1 TPH |

| Conveying Distance | 80 m (H) + 20 m (V) |

| Feed Point | Mill Fan & Dedusting Unit |

| No. of Feed Points | Battery of 20 No points. |

| Reception Point | Reception Silo |

| No. of Reception Points | 1 Nos. |

| USP of the System | Dense phase master slave pneumatic conveying system. |

| Dust Unloading System | ||

|---|---|---|

| Dust Discharge Type | Dry Dust Discharge | Wet Dust Discharge |

| Type of System | Telescopic Unloading Chute | Dust Conditioner |

| Design Philosophy | Telescopic design | Rotary paddle shaft |

| Unloading Capacity | 20 TPH | 20 TPH |

Protect your plant and workforce with proven technology.

Ensure Dust-Free & Safe Operations.

Gallery

Get in Touch with us Today!

Containing Address

130-131, Hindustan Kohinoor Complex, LBS Road, Vikhroli-West, Mumbai - 400083.