Case Study

- Home

- Case study demo

Pneumatic conveying, batching & weighing system for Talc

Customer Requirement

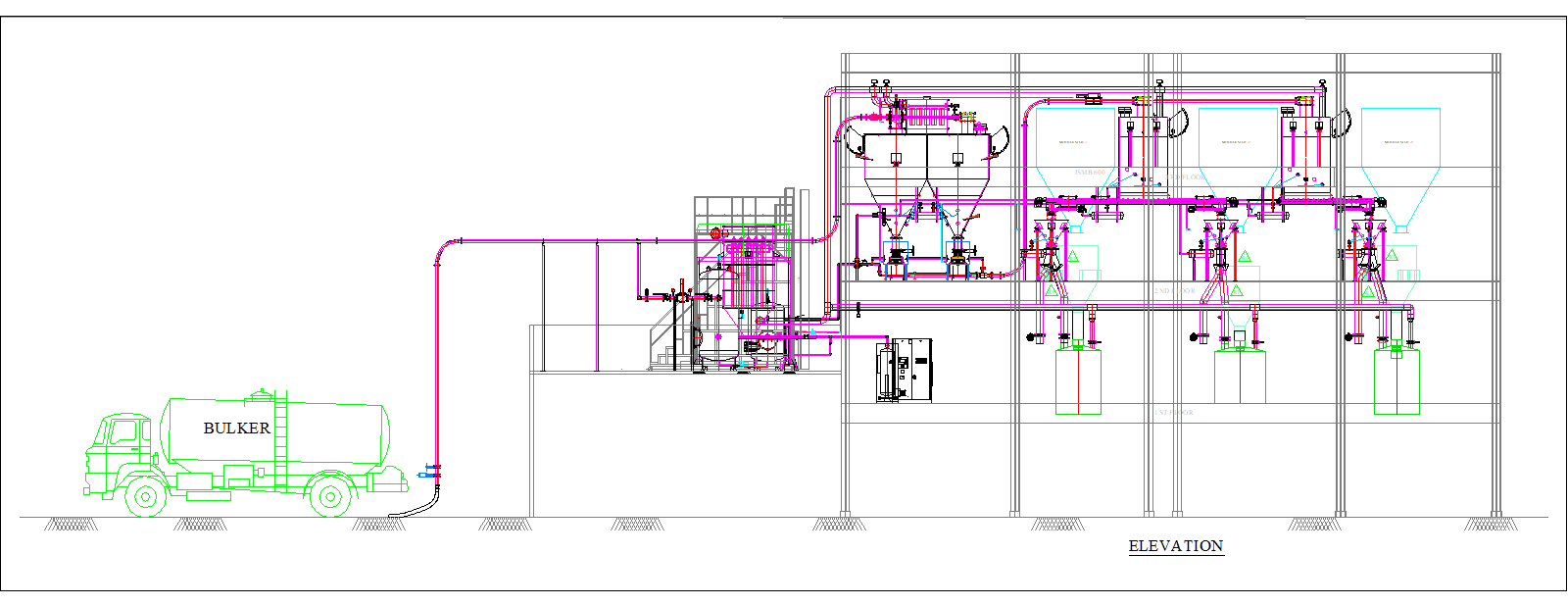

Reckitt Benckiser needed an integrated material handling solution for talc powder at their soap factory in Sitarganj. The system should cover the whole process from the unloading of bulkers to the storage in the reception silos. It should also include dense phase pneumatic conveying systems to reception hoppers and precise batching to mixers.

The process needed to be dust-free for a safer and cleaner environment. The system had to maintain the natural properties of talc by low-speed conveying. Repeatability of product quality requires precise batching. The system had to be completely integrated in the automation of the plant, which is operated on SCADA, so that efficient working could be accomplished. One major constraint was that there was little space within the existing building. This required that the design be space-saving but of high capacity. The need necessitated a bespoke double-cone silo and double dense phase conveying vessels. Yet throughput, safety, and availability could not be sacrificed.

Challenges Faced

Space constraints limited equipment layout and made standard designs impossible. The talc powder’s fine, dusty nature required strict dust control practices. Conveying at low velocities was necessary to avoid pipeline wear and keep the product’s quality intact.

The system also had to meet explosion protection regulations through the use of ATEX-rated, flameproof equipment such as dome valves. Maintaining ±1% batching accuracy through various batch sizes was no less significant. Integrating the installation into existing automation systems added complexity.

Solutions We Provided

- Small-scale pneumatic conveying and batching system entirely custom-designed to accommodate the site's space limitations

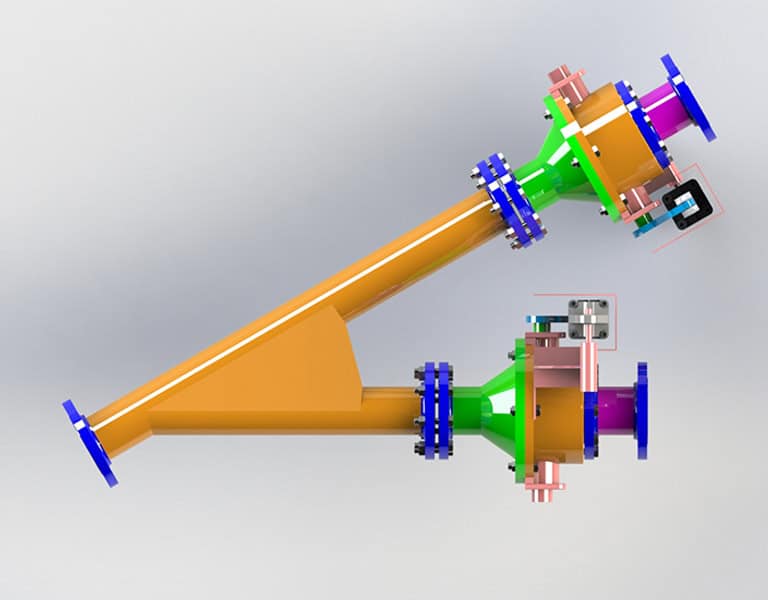

- Double-cone receipt silo with dual dense phase conveying tanks to optimize capacity within elevation restrictions

- Low-velocity, high-pressure dense phase conveying to safeguard material integrity and minimize pipeline wear

- ATEX-approved, flameproof components to conform to explosion protection requirements and regulations

- An entirely enclosed conveying line to provide dust-free operation throughout the whole system

- Feeding and injection solutions with gain-in-weight feeders with coarse and fine feed control for accurate material discharge

- 4-point load cells integrated for consistent ±1% batching accuracy

- Reception hoppers for optimal material flow and batch preparation

- Dust control systems consisting of filters and venting for a clean workplace atmosphere

- SCADA automation integration for end-to-end reliable operation and monitoring

- Space-efficient custom design optimizing performance in the tight building space constraints

Outcome/Results

The solution provided smooth, dust-free talc powder handling from bulker unloading to mixer feeding. Material integrity was maintained throughout. Wear of pipelines decreased considerably with low-velocity conveying. Batching consistently achieved ±1% accuracy needs for all batch sizes.

The system was installed within the limited space without any reduction in throughput. Safety was enhanced by explosion-proof, ATEX-approved components. SCADA integration complemented the explosive detection and monitoring capabilities. Boosted reliability and zero material loss were the result.

The outcome was a cleaner, greener production space. The system performed at peak levels while satisfying all space and safety requirements.

Project Summary Table

| Parameter | Specification |

|---|---|

| Material | Talc Powder |

| Bulk Density | 0.4 – 0.6 T/m³ |

| Particle Size | Fine |

| Temperature | Ambient |

| Nature of Material | Fine, free flowing, dusty |

| Moisture Content | Nil |

| Pneumatic Conveying System | ||

| Type of System | Bulker Unloading System | Dense Phase Pneumatic Conveying System |

| Conveying vessel | Bulker | Denseveyor |

| Conveying Capacity | 8 TPH | 1 TPH |

| Conveying Distance | 35 m (H) + 15 m (V) | 15 m (H) + 5 m (V) |

| Feed Point | Bulker Outlet | Reception Silo |

| Reception Point | Reception Silo | Reception Hopper |

| Explosion Protection | ATEX/Flameproof | ATEX/Flameproof |

| USP of the System | Dual outlet silo for reduced height. | Dual dense phase master slave pneumatic conveying system. Two sets of reception hoppers to feed into 3 sets of weigh feeders using long sets of separate coarse & fine screw feeders. |

| Batching, Weighing & Feeding Solution | ||

| Parameter | Specification | |

| Batch Size | 3.63 Kg, 20 Kg, 42 Kg, 63 Kg, other customized batches within this range | |

| Batching Accuracy | ±1% of the total batch quantity | |

| Weighing System | 4 pt live load cells | |

| Feeding Mechanism | Gain-in-weight feeders with coarse & fine feeding, integrated with 4 pt live load cells | |

| Cycle Time | Available time of approx. 10–15 minutes max. for batch creation & dumping into mixer | |

Looking for reliable conveying & batching systems?

Gallery

Get in Touch with us Today!

Containing Address

130-131, Hindustan Kohinoor Complex, LBS Road, Vikhroli-West, Mumbai - 400083.