Pneumatic conveying systems are considered the most efficient transportation means for bulk materials such as granules or powders. The food process industry makes use of these systems in order to move flour, wheat, coffee, pet food, chocolate, coffee, oats, spices, salt, dry milk and other such products seamlessly.

Food products in the form of granules or powder can be contained better when passed through the enclosed lines embedded within the pneumatic conveying units than the usual mechanical conveying systems.

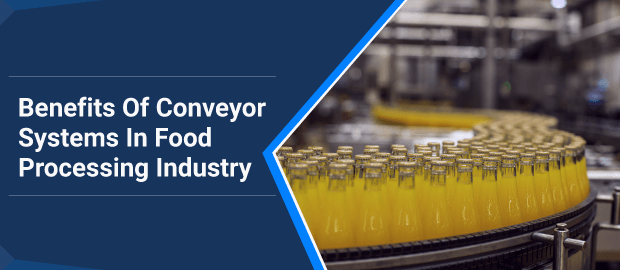

Discover the benefits of Macawber’s Conveyor Systems in food processing, and experience improved quality and productivity.

In this article, you will get a clear insight into some of the core benefits of conveyor systems in the food processing industry for you to be confident about implementing the same.

A] A Brief Explanation Of Pneumatic Conveying Systems

Pneumatic conveying systems are better known as the series of various pipelines that move specific products from one location to another through air pumping action. The products being transported through these systems pass through the airtight and enclosed pipelines, where airflow is combined with some form of pressure or gas.

For the food processing industry, pneumatic conveying systems help with not just transporting edible products safely but also with blending, weighing size reduction, and other such applications. Granules, powders, ingredients, dust products, and other such types of materials are often transported through the food pneumatic conveyors.

The pneumatic conveyors work upon the use of specific components such as air compressors, feeding devices, airtight pipelines, and others.

Discover the benefits of Macawber’s Conveyor Systems in food processing, and experience improved quality and productivity.

B] Advantages Of Using Pneumatics In Food And Beverage Industry

Before you talk to your pneumatic conveyor manufacturer to send you the best unit in their facility for taking your food and beverage business to the next level, it is important you get an insight into some of the benefits associated with this system. So, here are some of the benefits of food processing pneumatic conveyor systems for you to count on:

1. Boost Efficiency And Productivity

Pneumatic conveyors play a major role in allowing the food-grade material to move between multiple stages easily. These materials can move around in multiple directions, which makes it quite easy for you to manoeuvre them, even to the opposite ends of your processing plant. Modern systems are efficient as they help eliminate manual intervention for material unloading.

The overall efficiency of producing food products or beverages will reduce when you have a proper pneumatic conveying system in place. It is because, with such systems, you will be able to have control of the level and speed of production, which will minimise material loss or product wastage.

2. Better Quality Control

There are specific pneumatic conveying systems for the food & beverage industry. These systems are designed to be free from contamination and dust as they handle the movement of food-grade materials. So, to ensure the safe and efficient transportation of the food materials from point A to B, pneumatics is important. Importantly, apart from all equipment components being food grade, all air used for powder transfer is dry & free of oil and is to food grade norms or standards.

These conveyor systems are also easy to clean and are free from all forms of contaminants as far as beverages or foods are concerned. You will have better control over the quality of your food products when you use a pneumatic conveyor system in its production stages.

3. Reduced Risk Of Food Contamination

As the pneumatic systems come with an enclosed setup, the risk associated with product contamination is reduced, which ensures the plant remains cleaner for transporting food-grade materials. These piping systems are sealed units that automatically transport the food materials from point A to point B.

Due to the mechanism it has, the material won’t be exposed to lubricants, pests or other wear parts. In this way, there will be no risk of contamination in the pneumatic conveying systems, making it a better option than that of the open belt conveying systems.

4. Lower Maintenance

The pneumatic conveying systems have very few dynamic parts, for which they require only a minimal amount of maintenance. Every component, such as air compressor, pump, separator, tubing and in-feed device, can undergo repair jobs independently. Thus, there will be a limited amount of downtime, and the overall maintenance work will also be executed quickly.

Beyond easy maintenance, as the pneumatic systems have fewer moving parts than the mechanical systems, it is safer for the maintenance staff or operators to handle this machine. Thus, this simplicity is what makes the pneumatic system more efficient and reliable for the food processing industry.

Discover the benefits of Macawber’s Conveyor Systems in food processing, and experience improved quality and productivity.

5. Less Spillage and Dust Leakage

The product granules or dust will be contained better through the enclosed pipelines of the pneumatic conveyor, making the system well-connected. As the pipelines are enclosed, you can make sure that the product contamination that might be triggered due to the interference of moisture or dust from the outside will be significantly reduced.

There will be less dust leakage or spillage, which will ensure the food quality is top-notch. Beyond suppressing the contamination risks, the pneumatic conveying system will also keep the plant sanitised and clean, further enhancing the hygiene aspects.

6. Affordable

The pneumatic conveying units are comparatively more affordable than that of the mechanical systems. This is mostly because there are only a few electronic components, and the expansion of these systems is also affordable. The various teams working with the pneumatic conveyors require less training or ramp-ups when the new set of equipment is installed.

Thus, you will be saving a lot of money and time associated with recovering from downtimes. You will have to hire less human workers when you have a pneumatic conveyor in the food industry. Thus, it will help you save a lot on your wages, insurance covers and employment benefits.

7. Energy Efficiency

The operators will be able to optimise the energy usage and then reduce the overall cost by regulating the pressure within these systems. When you have the ability to control the pressure within the conveying system precisely, it means you will only be using a certain level of pressure or energy that’s needed for the application.

Such operational control will ensure that you are using less power to keep your food processing facility running. Therefore, you will be saving a lot on your energy bills. Following that, if you are using shorter paths for airflow, which needs less volume, it will then require smaller tubes, which adds up to the energy efficiency.

8. Minimising Manual Labor

When there were no conveying systems in place, people used to transport food-grade materials manually from one place to another. A large workforce was required for the process, which made the job slower and more strenuous. The companies were forced to hire more labourers to keep up the food production work.

But, with the pneumatic conveying systems being introduced, the food manufacturers started to save money on their employment expenses, such as training, retention, wages and others. Following that, manual labour was reduced as the pneumatic systems are mostly automated to handle long-distance travel for the food materials.

9. Reduced Accidents

Food plants tend to be more productive and safer when the right kind of pneumatic systems are put to use. When you install such a system in your facility, the need for workers will significantly reduce. There will only be supervisors at the site to look after the seamless work being executed by the machine. Thus, fewer people indicate fewer accidents at the site.

Due to automation, employees can now handle their industrial jobs without exposing themselves to various risks. For instance, there is no need for workers to carry loads, repeat mechanical movements and handle other such physical tasks. Thus, the risk of injury is reduced.

Discover the benefits of Macawber’s Conveyor Systems in food processing, and experience improved quality and productivity.

Conclusion

These are the major benefits associated with the use of pneumatic conveying systems for the food processing industry. If you are running a food production business and are dealing with various raw materials that need safe and hygienic transfers from one level to another, a pneumatic conveying system can be your ideal pick. It will not just help you maintain your food quality but will also help you keep your business running with limited or no downtime.

If you want to learn more about pneumatic conveying systems or want to get one for your facility, contact us!

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.