Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

India’s wastewater treatment market is growing rapidly to comply with increasingly stringent environmental requirements as well as sustainability drives, covering industrial and municipal wastewater treatment areas. State-of-the-art ETP technologies have allowed for cleaner production processes as well as resource recovery, while also helping to ensure regulatory compliance and safeguarding health with resource security.

Pneumatic conveying for effluent treatment handles dry solids like lime, activated carbon, filter media, and pneumatic conveying of dried sludge with enclosed, dust-free transfer from dewatering to dosing and storage. These systems eliminate manual handling, prevent spillage, and ensure hygienic feeding to reactors, silos, and chemical dosing stations within pneumatic conveying for wastewater treatment plants.

Discover Proven ETP Pneumatic Conveying Solutions Now

Bulk Materials Handled

- Dry fine powder, granular powder

- Good flowability

- Abrasive in nature

- Moderately powdery

ETP operations require reliable transfer of lime (for pH control/coagulation), soda ash, activated carbon, filter media, and pneumatic conveying for sewage sludge post-dewatering. Sludge conveying systems in effluent treatment plants have to operate in complex plant layouts ranging from dewatering presses to storage silos, reactors, and critical dosing points. After the dewatering process, the sludge lumps will pass through a lump breaker and will then be conveyed to the destination using a pneumatic conveying system.

Solutions Offered by Macawber

Dense Phase Pneumatic Conveying

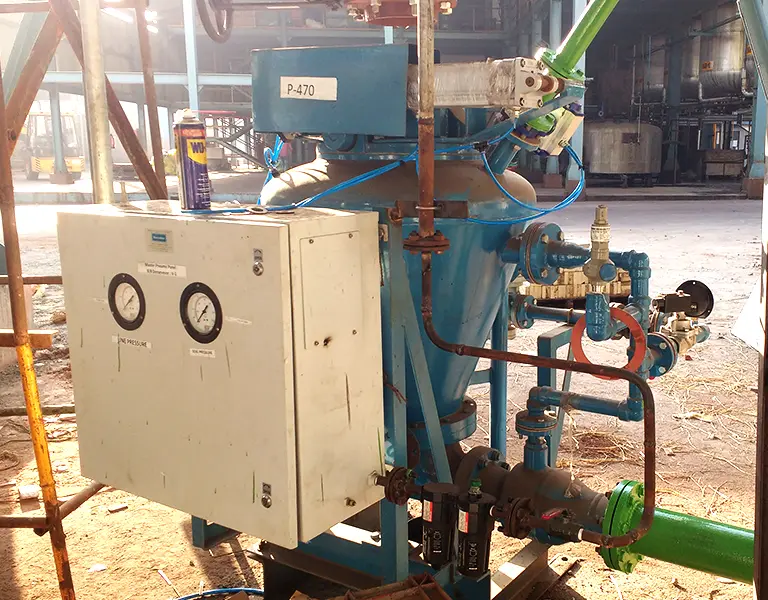

Lime is an important reagent in ETP pH neutralisation and coagulation. Macawber’s dense phase pneumatic conveying systems are used to transport lime from jumbo bags to storage silos and various dosing tanks through dense phase pneumatic conveying for sludge and chemical applications. Denseveyor units with capacities from 1 TPH to 20 TPH provide gentle, low-velocity transfer that protects both material quality and pipeline integrity while serving as a turnkey pneumatic conveying system for wastewater treatment requirements.

Lean Phase Pneumatic Conveying

Lean phase pneumatic conveying systems efficiently handle dry chemicals like soda ash and activated carbon at high velocity. Macawber supplied a complete pneumatic conveying system equipped with lump breakers to manage aggregates, achieving 5-10 TPH for continuous ETP operation. These closed systems ensure clean, reliable feeding to dosing units while minimising manual handling across pneumatic conveying for wastewater treatment plants.

Bulker Unloading Systems

Large ETP facilities receive lime via closed bulkers requiring fast, dust-free transfer to storage silos. Macawber’s bulker unloading systems with 10-30 TPH capacity integrate seamlessly with primary pneumatic circuits, featuring Dome valves for positive shut-off and rotary airlock valves for metering into conveying lines.

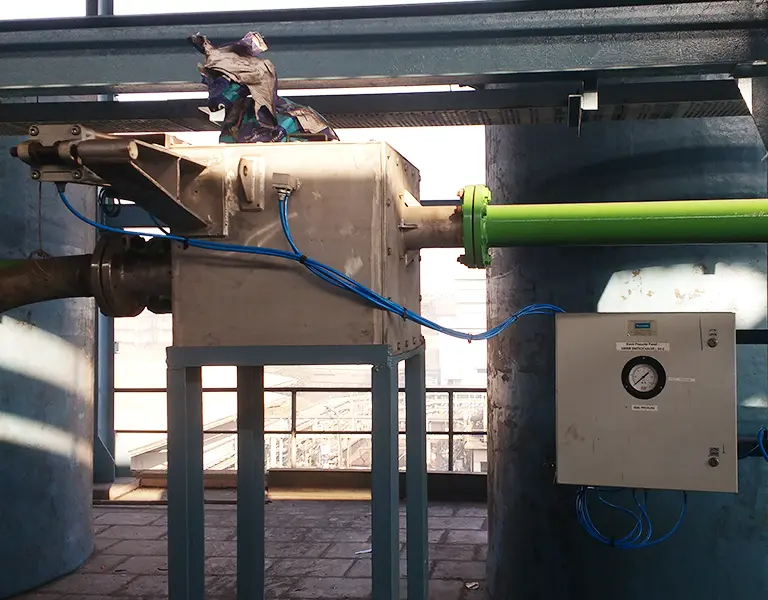

Mechanical Sludge Dryer Integration

Macawber’s 20-meter mechanical sludge dryers with VFD-controlled rotating spreaders and linear-actuated height adjustment complement systems by pre-conditioning of dried sludge for transfer to storage or dosing.

De-Dusting & Filtration

Bag filters and bin vent filters capture fines generated during dry sludge powder handling and powder chemical dosing. Diverter valves route pneumatic conveying systems for sludge handling streams between multiple silos while maintaining airlock integrity at all transfer points.

Plant Automation

Macawber integrates PLC/SCADA controls across complete material circuits from bulker unloading through dosing, optimising sludge conveying systems in effluent treatment plants with real-time flow monitoring, inventory tracking, and automated recipe delivery to reactors.

Products Deployed in ETP Applications

- Denseveyor units for lime and dense phase pneumatic conveying for sludge circuits

- Dome valves with hard coatings for pressure vessel discharge

- Diverter valves multi-silo or multi-preparation tank routing

- Bag filters transfer points and silo vents

- Wear-resistant bends

- Bin vent filters for capturing dust emission to nature

- Wear-resistant bends for the pneumatic conveying system after sludge dewatering

- Bulker unloading systems with 10-30 TPH capacity

- Screw conveyors and rotary airlocks for precise chemical dosing

- Mechanical sludge dryers pre-condition the material for pneumatic transfer

Optimise Wastewater Treatment Material Flow Today

Engineering Advantages for ETP Duty

ASME Pressure Vessel Compliance

Macawber fabricates vessels to ASME codes, ensuring safe operation with combustible dusts common in pneumatic conveying for effluent treatment applications under cyclic pressure loading.

Specialised Valve Coatings

Dome valves receive ceramic and tungsten carbide coatings optimised for lime and sludge dust, extending service life in a continuous pneumatic conveying system for sticky sludge service.

Optimised System Sizing

Vessels and pipelines sized precisely for ETP throughput and air requirements, balancing energy efficiency with pneumatic conveying of dried sludge performance across varying plant layouts.

Generous Filtration Design

Macawber specifies oversized bag filters, preventing backpressure during rapid lime vessel discharge cycles common in pneumatic conveying for sewage sludge operations.

As a leading pneumatic conveying system manufacturer and supplier, Macawber delivers proven turnkey pneumatic conveying systems for sludge handling in wastewater treatment engineered for the corrosive, high-duty conditions of modern ETP facilities.

FAQ's

Lime for pH control, soda ash, activated carbon, filter media, and dried sludge powder require dust-free pneumatic transfer through pneumatic conveying for effluent treatment circuits. These systems ensure hygienic handling from storage silos to precise reactor dosing stations.

Dense phase pneumatic conveying for lime uses low-velocity slug flow to minimise pipeline wear while ensuring reliable delivery from jumbo bags to multiple dosing tanks. Macawber systems handle 1-20 TPH with proven ETP performance.

Enclosed pneumatic conveying for wastewater treatment plants eliminates manual handling, prevents dust emissions, and automates precise chemical powder dosing. This maintains consistent treatment chemistry, reduces operator exposure, and ensures regulatory compliance across complete material circuits.

Macawber supplies sludge conveying systems in effluent treatment plants from 1 TPH lime dosing systems to 30 TPH bulker unloaders. All systems are customised to specific plant layouts, throughput requirements, and material characteristics for optimal performance.

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.