Gentle and Dust-Free Conveying of PET Chips for SRF’s BOPET Film Line

- Home

- Case Study

- Gentle and Dust-Free Conveying of PET Chips for SRF’s BOPET Film Line

Gentle and Dust-Free Conveying of PET Chips for SRF’s BOPET Film Line

Customer Requirement

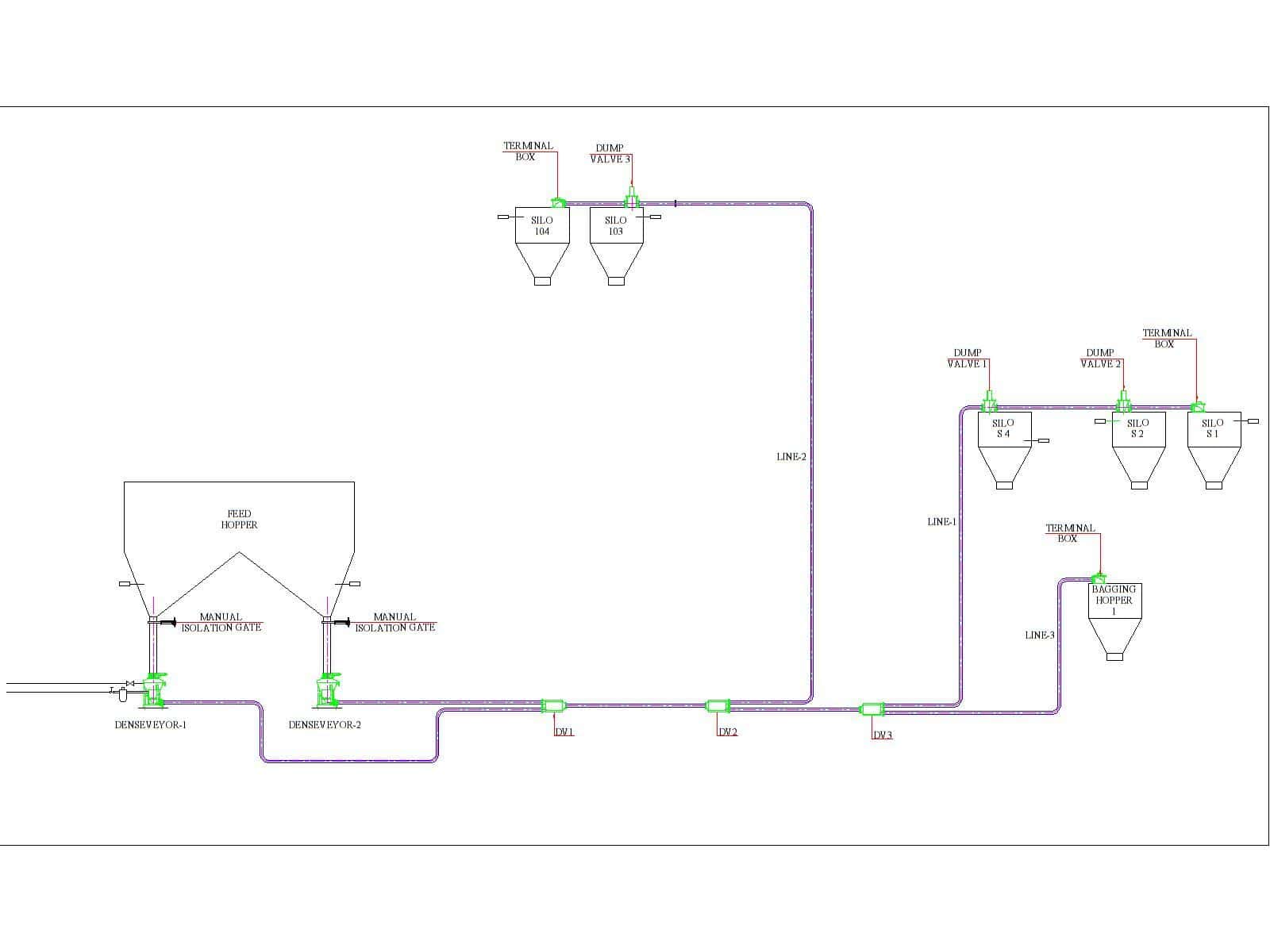

Our customer, a leader in packaging films, wanted a safe, efficient, and contamination-free material handling system for its advanced BOPET film manufacturing facility. The solution had to convey the PET chips from feed hoppers to process silos, extrusion units, and downstream film lines while maintaining chip quality without dust generation.

PET is prone to friction and impact, so the slightest damage can damage the quality of the film. Therefore, the system needed to operate at low velocity, maintain material integrity, and integrate well with SRF’s automation controls. In this regard, the company collaborated with Macawber Engineering, a well-known pneumatic conveying system manufacturer in India with expertise in the latest dense-phase technology and experience in handling delicate materials.

Challenges Faced

Long-distance transportation of PET chips required the precise control of air velocity and pressure. The granular form of the material (3–5 mm) is susceptible to breakage and fines if conveyed through high-velocity dilute-phase systems. Such degradation would affect the optical and physical quality of BOPET films.

Further, the SRF layout had to transport over 80 metres along a horizontal direction and 30 metres along a vertical direction, connecting feed hopper to six reception silos. Ensuring consistent throughput at minimum pressure drop and minimum energy consumption was a big task. It also had to be completely enclosed to eliminate dust emissions and ensure operator safety while remaining fully automated with blockage and overpressure alarms.

Solutions We Provided

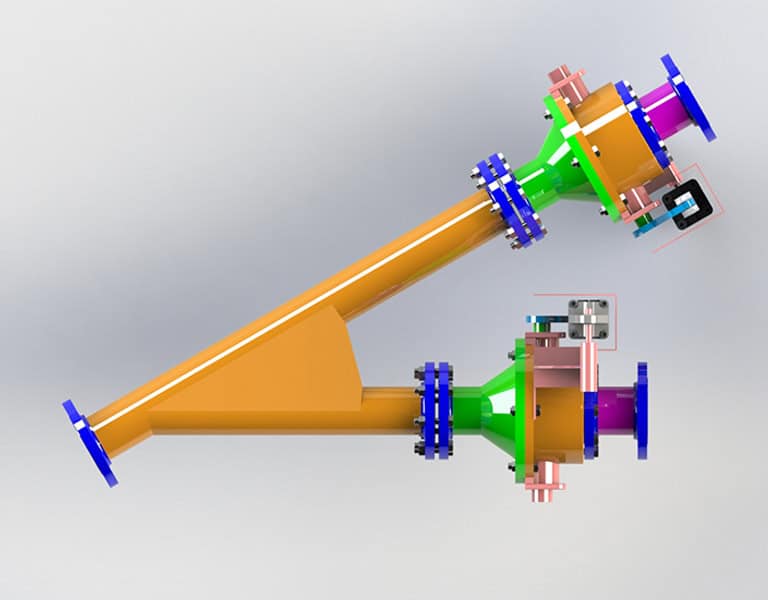

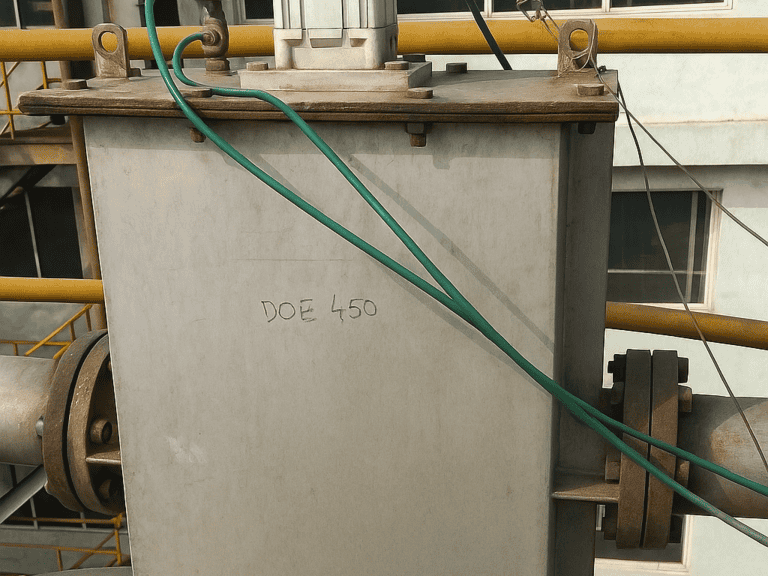

A Dense Phase Pneumatic Conveying System, developed by Macawber Engineering, was installed to fulfil the operation and quality requirements of customer.

- The developed Denseveyor vessel-based system conveyed the PET chips under low-velocity and high-pressure conditions while reducing surface abrasion and material degradation.

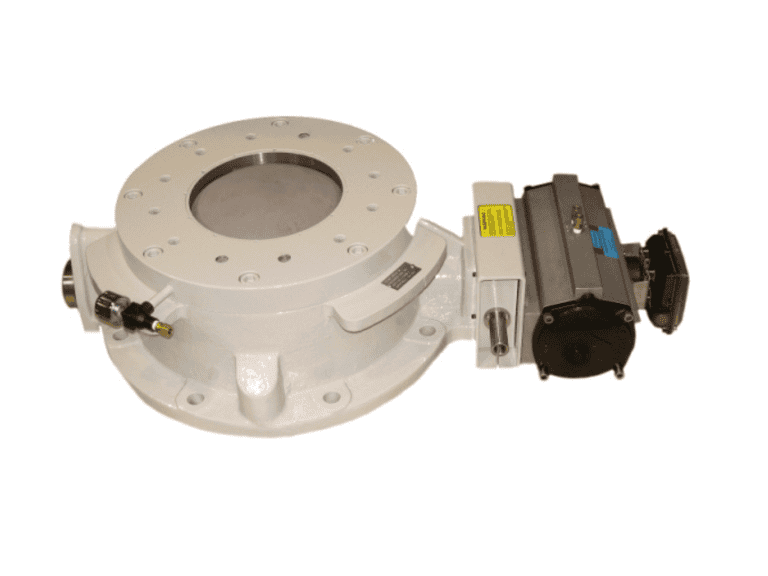

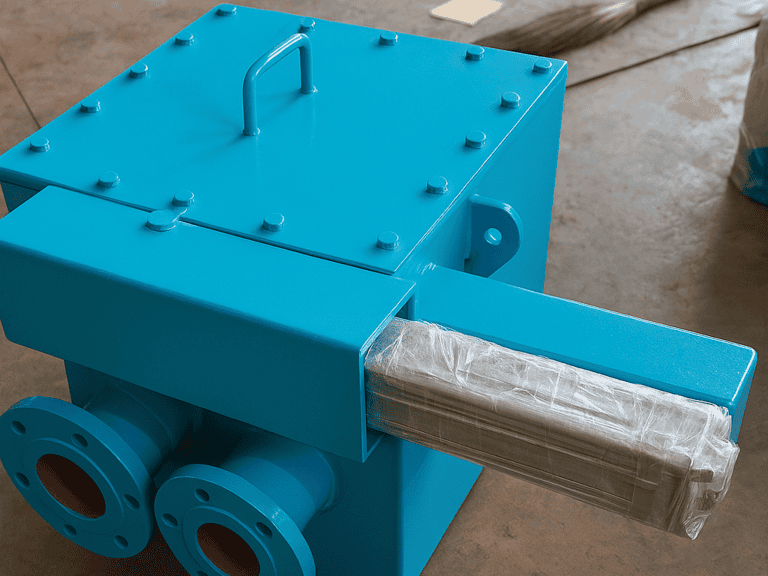

- Installed precision-engineered diverter valves and dump valves to manage smooth routing between multiple feed and discharge points.

- In the discharge areas, it has a pulse-jet dust collection system to ensure that the operation is dust-free.

- Installed an automatic sequencing, real-time monitoring and adaptive cycle timing PLC-based control system.

- Implemented a PLC-based control system that provides automatic sequencing, real-time monitoring, and adaptive cycle timing.

- Added intelligent safety features, such as blockage detection, filter load alarms, and overpressure safeguards for continuous operation.

- Applied Leveraged dense-phase pneumatic conveying systems to provide a high-performance, low-maintenance, energy-efficient solution.

This integrated system met the technical benchmarks of customer for all its projects and aimed at reliability, cleanliness, and long-term operational efficiency.

Results

The installed system turned customers entire PET chip conveying operation into a completely automated, enclosed, and dust-free process. Gentle material handling, enabled by dense-phase technology, preserved the resin structure and ensured high-quality output of BOPET film.

The conveying capacity achieved by the system was 10 TPH per feed point, ensuring stable performance over long conveying distances and minimising wear and reducing maintenance. Automation reduced manual involvement, improved safety, and resulted in higher process reliability.

Energy efficiency also improved significantly, with virtually eliminating dust emissions for a cleaner and more sustainable workplace. At the close of the commissioning process, all the performance and quality considerations were achieved, with the project still serving to support the reputation of Macawber Engineering in developing innovative application-driven solutions to enhance reliability in the processes and integrity of products. Explore more about their advanced dense-phase pneumatic conveying systems designed for delicate and high-value materials.

Project Summary Table

| Parameter | Specification |

|---|---|

| Material | PET Chips |

| Bulk Density | 0.8 T/m³ |

| Particle Size | Granular 3 to 5 mm |

| Temperature | Ambient |

| Moisture Content | Nil |

| Type of System | Dense Phase Pneumatic Conveying System |

| Conveying vessel | Denseveyor |

| Conveying Capacity per point | 10 TPH |

| Conveying Distance | 80 m (H) + 30 m (V) |

| Feed Point | Feed Hopper |

| No. of Feed Point | 2 Nos. |

| Reception Point | Reception Silo’s |

| No. of Reception Point | 5 Nos. |

Discover how our dense-phase conveying systems ensure gentle, dust-free, and efficient PET chip handling for high-quality BOPET film production.

Gallery

Get in Touch with us Today!

Containing Address

130-131, Hindustan Kohinoor Complex, LBS Road, Vikhroli-West, Mumbai - 400083.