In the high-pressure, high-dust environment of a blast furnace gas cleaning plant (GCP), ensuring safe and reliable isolation of gas lines is critical. One of the most robust and efficient solutions for this demanding application is the dome valve, a specialised valve engineered for tough conditions where conventional valves often fail.

In this comprehensive blog post, we will explore what a dome valve is, its applications in the blast furnace gas system, and more. Keep reading!

The Role of Gas Shut-Off in a Gas Cleaning Plant

Blast furnace gas is a by-product of ironmaking and contains a mix of carbon monoxide, carbon dioxide, nitrogen, and fine particulate dust. Before this gas can be reused in stoves, power generation, or heating, it must pass through several cleaning stages, such as:

- Dust catchers

- Cyclones

- Electrostatic precipitators or bag filters

- Wet scrubbers

The gas shut-off valve prevents gas leaks when gas passes through several cleaning stages, ensuring safety and operational efficiency.

Ensure safe gas shut-off with dome valves.

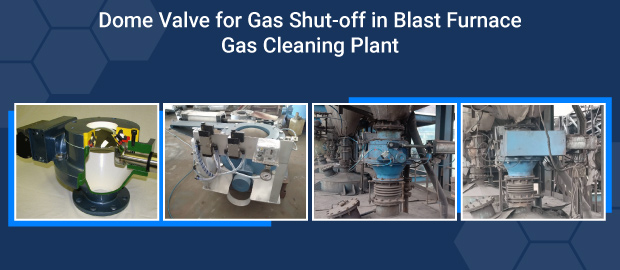

What Is a Dome Valve?

A dome valve is a robust, pneumatically/hydraulically actuated valve designed to handle:

- Dense and abrasive materials

- High differential pressures

- Fast opening/closing cycles

Its key feature is a dome-shaped sealing element that moves across the valve body to provide full bore opening and tight shut-off, even with solids present in the flow path.

Applications of the Dome valve in Blast Furnace Gas Systems

1. Isolating Gas Lines Between the Dust Catcher And The Downstream Equipment

Dome valves for blast furnace applications are used to isolate and prevent leakage of hazardous gas from the dust collector outlet to the equipment downstream in blast furnace gas cleaning plants. Their robust sealing capability, even in dusty conditions, ensures safe shutdowns for maintenance or emergencies.

2. Shutting Off The Gas During Maintenance Of Cyclones Or Filters

Dome valve for gas shut-off provides a reliable shut-off of gas flow during maintenance of cyclones or filters in blast furnace gas cleaning systems. Their ability to seal tightly, even in dusty environments, ensures worker safety and prevents gas leakage.

3. Protecting Instrumentation Or Downstream Blowers From Dust-Laden Gas

Dome valves protect sensitive instrumentation and downstream blowers from dust-laden blast furnace gas by providing a secure and reliable gas-tight seal. Their ability to handle abrasive particles without leakage prevents equipment fouling and damage. As a result, it ensures consistent performance, reduces maintenance needs, and enhances the overall reliability of gas cleaning operations.

4. Gas-Tight Sealing In Pressure Vessels Used For Dust Collection Or Storage

Dome valves, a gas shut-off valve for blast furnaces, ensure gas-tight sealing in pressure vessels used for dust collection or storage in blast furnace systems. Their robust design allows them to seal effectively even with dust present, maintaining system pressure and preventing gas leakage.

5. Integration With Dense Phase Conveying

In systems where dust collected from scrubbers or filters is pneumatically conveyed, dome valves are often used on pressure vessels or ash hoppers. Here, they provide an airtight shut-off between the vessel and pipeline during pressure cycling, ensuring safe and clean transfer of blast furnace GCP dust.

Engineering Considerations

When supplying dome valves for Blast Furnace GCP applications, Macawber, a leading manufacturer of pneumatic conveying systems in India, always assesses the following to provide the best valve for gas shut-off in blast furnace applications:

- Operating pressure and temperature of the gas line

- Dust particle size and abrasiveness

- A leakage-tight valve to ensure zero leakage

- Integration with plant control systems (e.g., PLC/SCADA)

- Ease of maintenance and availability of wear parts

Installing air purging systems around the sealing dome can also enhance performance by keeping sealing surfaces clear of dust build-up.

Ensure safe gas shut-off with dome valves.

Conclusion

For blast furnace gas cleaning plants, Macawber Engineering, one of the largest dome Valve manufacturers in India, offers unmatched performance in gas shut-off applications where high pressures, fine dust, and safety-critical isolation are involved. Their durability and sealing integrity make them a preferred choice over conventional valves, especially in the steel industry’s most challenging operating zones. We have positioned ourselves as a top manufacturer of dense phase pneumatic conveying systems in India. Contact us today!

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.