Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

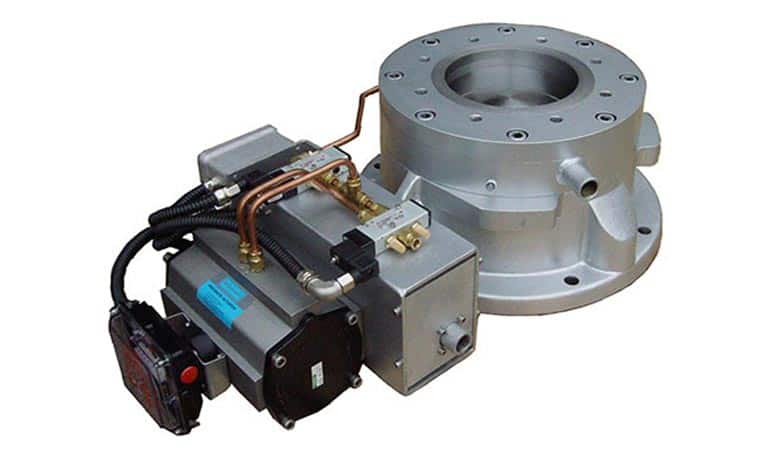

Dome Valve Manufacturer

As a renowned pneumatic conveying system manufacturer in India, Macawber is the inventor & patent holder of the Dome valve design, which was secured as a patent in 1979. A Dome Valve is a process inlet/outlet full-bore opening valve with an opening & closing hemispherical dome element. The unique closing and sealing technology enables dome components to be completely shielded from the material flow, allowing unrestricted material flow through the valve.

Macawber Engineering Systems India is a prominent dome valve manufacturer in India, we use the highest-grade materials and state-of-the-art technologies to manufacture DV that efficiently caters to industry standards. Macawber offers Dome Valve in different material types such as cast steel, cast iron, stainless steel, alloy steel, and coatings of frit-based ceramic, tungsten carbide & hard chrome, etc. We also offer Dome valve spares for a wide range of industries.

Dome Valve Key Features:

- Macawber offers the latest DV-2 design which has proven ideal for long-term usage.

- Our DV has a full-bore opening with an inflatable seal design for pressure-tight closure.

- As a prominent dome valve supplier, we designed standard Dome valve models that can hold up to 400 deg.C temperature and a pressure range of up to 7 bar(g).

- We guarantee the longest life of our heavy-duty and wear-resistant inlet valve.

- As a renowned Dome valve manufacturer, we offer robust DV that can handle extremely abrasive materials and operate at high-pressure differentials.

- Our DV’s hemispherical shape and its locus of motion ensure that the Dome valve does not buckle under heavy column load conditions.

- Macawber DV’s are rated for a 1 million maintenance-free cycle and can withstand harsh weather conditions while maintaining high tensile strength.

- Splined shaft-type ensures play-free tight shaft-dome design and can work in bulkhead (vertical) and In-line (horizontal) configurations.

- Our DVs can be used in various non-standard applications and diverters (DV-type vacuum drop through the chamber for RVD, DV-type Y-diverter valve).

- We have designed our DVs for various MOCs and linings/material treatments such as Frit-based ceramic coating, Tungsten carbide coating, Ni-Cr alloy usage, heat treatment etc.

Our several other products like pneumatic ash handling systems, dense phase pneumatic conveying systems, and pneumatic dump valves are known for their state-of-art technology and robust functionality with long-lasting guarantees.

Contact us today and boost your business with our advanced and robust conveying systems!

Frequently Asked Questions

The size of the dome valve can vary from 100 mm to 800 mm. However, choosing the correct dome valve size as per requirement is crucial to mitigate premature or unexpected failure.

The selection of material to make dome valve seals can be based on the specific application requirements including temperature, pressure, and chemical compatibility.

Product Video Watch Now

Kedar Kamath

Kedar Kamath is a highly accomplished bulk material handling professional with 14+ years of experience at Macawber Engineering Systems India Pvt Ltd. Starting as a junior sales engineer, he progressed to his current role heading Business Development and Sales. His expertise encompasses proposals, estimations, sales, marketing, design engineering, project execution, and factory operations. Mentored by industry leaders, Kedar's technical acumen (B.Tech in Electrical Engineering, VJTI, Mumbai) and innovative approach deliver tailored solutions. He's passionate about sustainable practices and driving excellence within the industry.